Rating

0.0(0)

Tags

Explore Top Notes Note

Note Studied by 9 people

Studied by 9 people Note

Note Studied by 28 people

Studied by 28 people Note

Note Studied by 28 people

Studied by 28 people Note

Note Studied by 133 people

Studied by 133 people Note

Note Studied by 23 people

Studied by 23 people Note

Note Studied by 4 people

Studied by 4 people

CLIMATE CHANGE REVIEW

5.0 Stars(1)

Much Ado about Nothing

5.0 Stars(1)

The Cultural Landscape Chapter 6: Religion

5.0 Stars(1)

Chapter 1: Scientific Foundations of Psychology

4.5 Stars(4)

Aller Test

5.0 Stars(1)

Chapter Twelve: Substance Use and Addictive Disorders

5.0 Stars(1)

Supply Chain Test #2

Intro to Supply Chain Ch. 5-8 Notes

Chapter 5: Purchasing Management

Defining Procurement and Purchasing

Procurement

- Procurement - the process of selecting and vetting suppliers, negotiating contracts, establishing payment terms, and the actual purchasing of goods and services

- Concerned with acquiring all the goods, services, and work vital to an organization

- Overarching or umbrella term within which the action of purchasing can be found

- Part of the Sourcing stage of the SCOR model

- Purchasing - the action of obtaining merchandise, capital equipment, raw materials, services, or maintenance, repair, and operating (MRO) supplies in exchange for money or its equivalent from a third party

- Transactional function of procurement for goods or services

- “Purchasing” is also commonly used to represent the function of, and the responsibility for, acquiring materials, supplies, and services for an organization

- Might be a separate department within a company, or it might be part of the supply chain management department within a company

Purchasing Terms

- Purchase requisition - an internal document that defines the need for goods and/or services

- Does not constitute a contractual relationship with an external party

- Generated by a user department to notify purchasing personnel of items to order, their quantity, and the timeframe

- May also contain the authorization to proceed with the purchase

- Purchase order (PO) - an external commercial document; official offer issued by a buyer to a seller to acquire goods or services

- Used to control the purchasing of products and services from external suppliers

- Indicates types, quantities, and agreed prices for products

- Request for information (RFI) - standard business process whose purpose is to collect written information about the capabilities of various supplies

- Request for proposal (RFP) - detailed capabilities document used to determine a supplier’s capability and interest in the production of a product or service

- Request for quote (RFQ) - document used to solicit bids (i.e., price and delivery) from interested and qualified suppliers for goods or services that the organization needs to obtain

The Primary Objectives of Purchasing

- Ensure an uninterrupted flow of materials and services at the lowest total cost

- Improve the quality of the finished goods produced

- Optimize customer satisfaction

Purchasing Process Steps

- A need is identified, and a Purchase Requisition is issued

- Request for goods or services submitted to the Procurement/Purchasing organization for action. Typically initiated by a user within an organization

- Obtain authorization as necessary

- A Purchase Requisition may be routed to an authorized approver(s) depending on the type of material and service being requested and/or the dollar value of the request

- Identify and evaluate potential suppliers

- May be determined from a list of approved suppliers

- Alternatively, a Request for Information (RFI) may be used to collect information from potential suppliers on their capabilities in supplying the material or service

- Make supplier selection

- If the buyer already knows which supplier they will buy from, move to Step 3

- If not, a competitive bidding process may be initiated through the use of a Request for Proposal (RFP) or a Request for Quotation (RFQ)

- Buyer issues a Request for Proposal for items which have not been previously purchased, or not purchased from a specific supplier being evaluated. supplier(s) provide their proposal to supply the item(s) including price and delivery

- Buyer issues a Request for Quotation (RFQ) for routine or repeat purchased items. supplier(s) provide a price and delivery quote on the specific item(s) requested

- A Supplier is selected from the RFP or RFQ bids received based on criteria determined by the Buyer, including price, availability, quality, delivery costs, etc.

- Purchase order is created and delivered to the supplier

- To inform the supplier of the intent to purchase

- To identify the item(s) to be procured, the quantity required, the requested delivery date(s), the price to be paid, the delivery location, and any terms and conditions that relate to the order.

- The PO is the Buyer’s formal offer to the supplier to obtain the item(s)

- Supplier confirmation of the purchase order

- The Supplier formally agrees to supply the item(s) per the specifications, terms, and conditions described on the Purchase Order.

- The Purchase Order then becomes a legally binding contract between the Buyer and the Supplier for the item(s) specified

- The PO becomes a binding contract only when accepted and confirmed by the supplier

- Fulfillment

- Supplier delivers items to the buying organization as per the PO

- Receipt of goods

- Once the items arrive at the designated location, the buyer will typically conduct some form of receipt process

- Receipt process - items are checked to ensure that they conform to the details of the PO, including quality and quantity

- A confirmation of receipt may also be sent to the supplier

- Once the items arrive at the designated location, the buyer will typically conduct some form of receipt process

- Invoice and reconciliation

- Supplier prepares an invoice for the items order. The invoice either accompanies the items or is sent separately to the buyer

- Invoice may need to be reconciled to the purchase order and goods receipt before payment is made

- 3-way match - invoice, purchase order, and goods receipt must match

- Payment

- Payment is processed using an appropriate payment method assuming the items are received and meet all the criteria established on the PO

- Close out the purchase order

- If the PO has been received complete and all terms and conditions have been met, the PO should be closed out in the purchasing system

- If PO has not been received complete, a decision must be made as to whether the balance will be received or the order will be considered complete and closed out

- Analysis

- Measurements of the efficiency and accuracy of procurement process

- Specific PO data and information captured and used during period supplier performance meetings

e-Procurement

- e-Procurement - describes the automation through web-enabled tools of the non-strategic and transactional activities that would otherwise consume the majority of a buyer’s time

- E-procurement tools typically automate all or part of the following processes

- Solicitation tools such as RFI, RFP, RFQ

- Execution and analysis

- Reverse auction capabilities

- Automation provides increased visibility of all purchases

- Basic e-procurement process:

- Electronic purchase requisition and/or purchase order

- Invoice

- Might be one with the receipt

- Payment

- High-dollar purchases will also generally include:

- authorize=ation of the purchase order

- Reconciliation of the invoice

- Advantages

- Time savings - reduction in time between need recognition and the release and receipt of an order

- Cost savings - lower overhead costs in the purchasing area

- Accuracy - a reduction in errors; virtual elimination of manual paperwork

- Real time - improved communication both within the company and with suppliers

- Management - purchasing personnel spend less time on processing of purchase orders and invoices, and more time on strategic value-added purchasing activities

- Mobility - access virtually anywhere

- Trackability - real-time status tracking

- Benefits to the suppliers

The Financial Significance of Purchasing

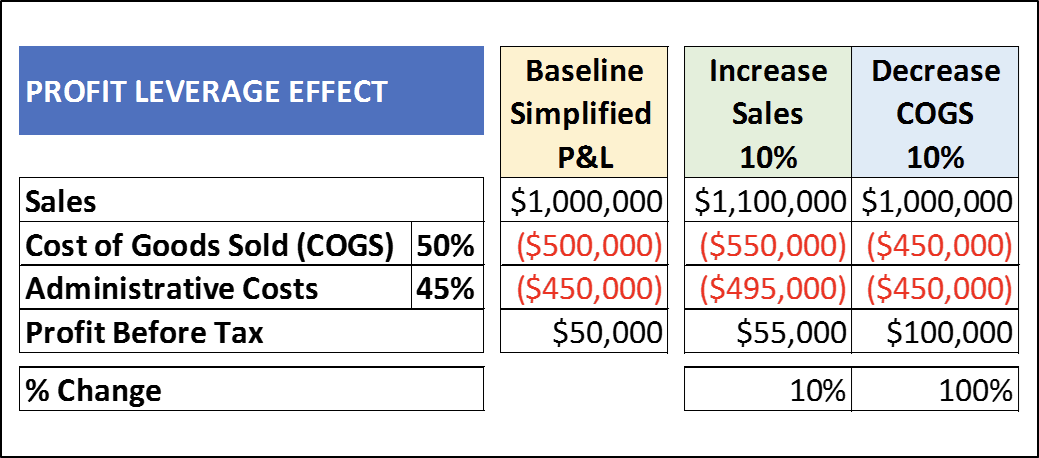

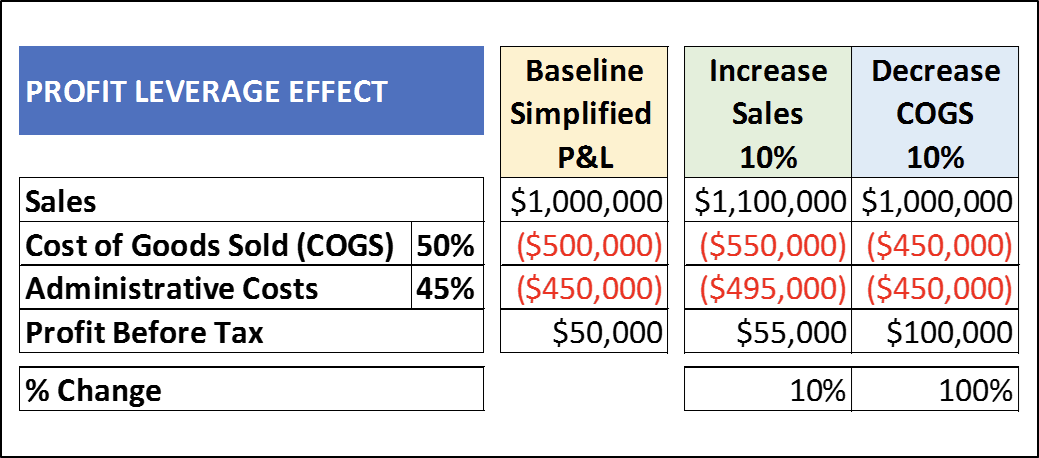

Profit-leverage Effect

- Profit-leverage effect - Decrease in purchasing expenditures directly increases profits before taxes

- Assuming no decrease in quality or purchasing total cost

- Bottom line impact is $ for $

- 10% Cost Reduction generates significantly more Profit Before Tax than does 10% Sales Increase

- One of the main reasons procurement managers are under significant pressure from senior management to reduce purchase costs

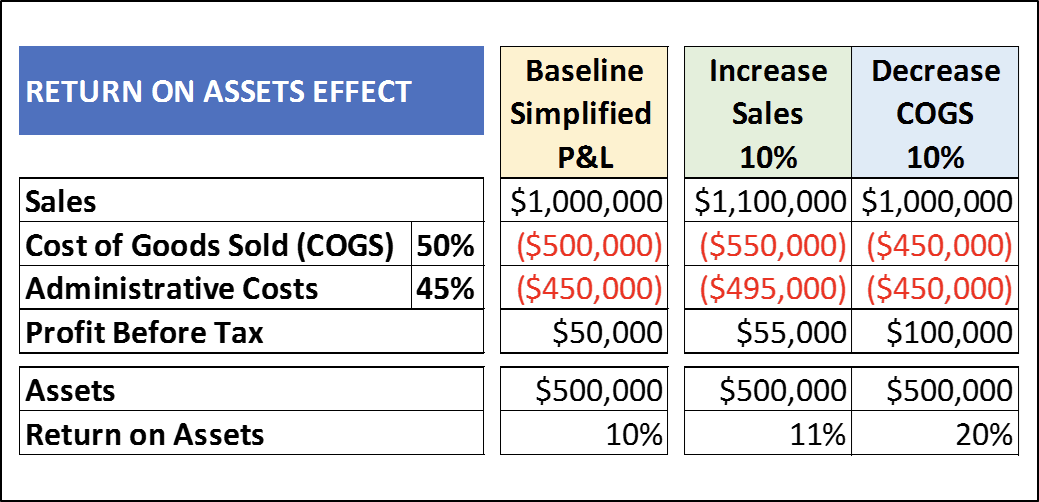

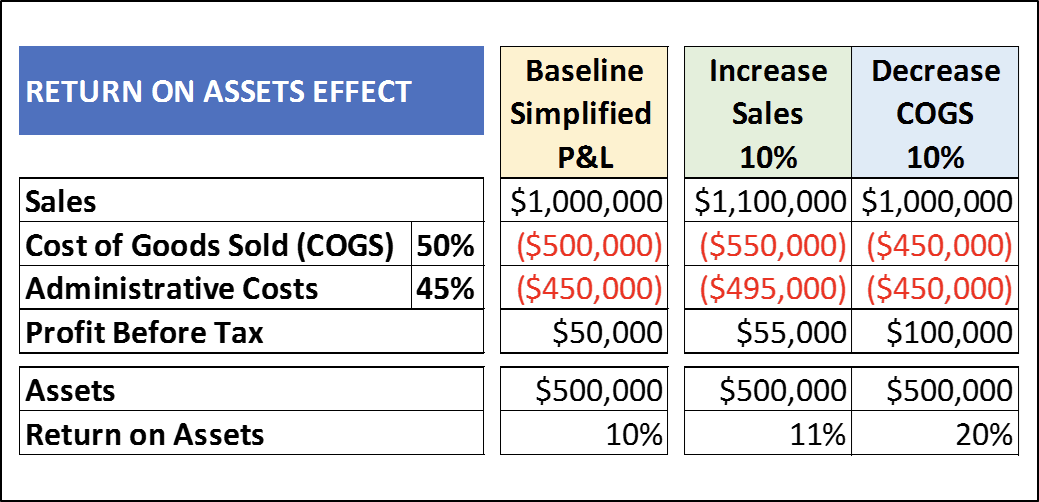

Return on Assets Effect

- Return on Assets (ROA) effect - a high ROA indicates managerial prowess in generating profits with lower spending

- ROA = Profit before tax / Assets

- A 10% Cost Reduction generates a significantly higher Return on Assets than does a 10% Sales Increase, given the same number/value of assets

Inventory Turnover Effect

- Inventory turnover effect - increased inventory turnover indicate optimal utilization of space and inventory levels, increased sales, avoidance of inventory obsolescence

- Inventory is an asset but also tied-up capital

- The purchasing function in an organization is frequently responsible for Supply Management and therefore plays a large part in the amount of inventory the company holds

- Inventory turnover - represents the number of times the company sold through inventory in a given time period

- Inventory turnover = COGS / Average Inventory

- High turnover ratio: beneficial because it means the company is generating sales efficiently to sell inventory

- Low turnover ratio: unfavorable because it means the company is not selling through products efficiently. Company is likely making/buying too much inventory for demand and may end up throwing out expired or unsaleable products

Total Cost of Ownership (TCO)

- Total cost of ownership (TCO) - the sum of all the costs associated with every activity

- Purchase price of an item is very important, but it is only one part of the total cost of ownership

- 4 elements of cost (QSDP):

- Quality

- Service

- Delivery

- Price

- TCO = Quality + Service + Delivery + Price

- Main TCO insight: acquisition cost if often a very small portion of the TCO

- Accounts for only 25-40% of the total cost for most products

- Other factors beyond purchase price must also be considered

- Quantity discounts - may be offered to encourage buyers to purchase larger quantities

- Cash discounts - may be offered for prompt payment of invoices

- Ex.: 2% 10, Net 30

- Value-added services - may be offered such as:

- Special delivery

- Special packaging

- Preparation of promotional displays

- Subassembly operations in a supplier’s plan

- Administrative expenses - associated with procurement activity itself such as:

- Screening potential suppliers

- Negotiation

- Order presentation

- Order transmission

- Poor supplier quality costs related to defective finished goods must also be considered. Costs such as:

- Scrap

- Rework

- Recycling

- Recovery of materials

- Warranty administration

- Repair costs

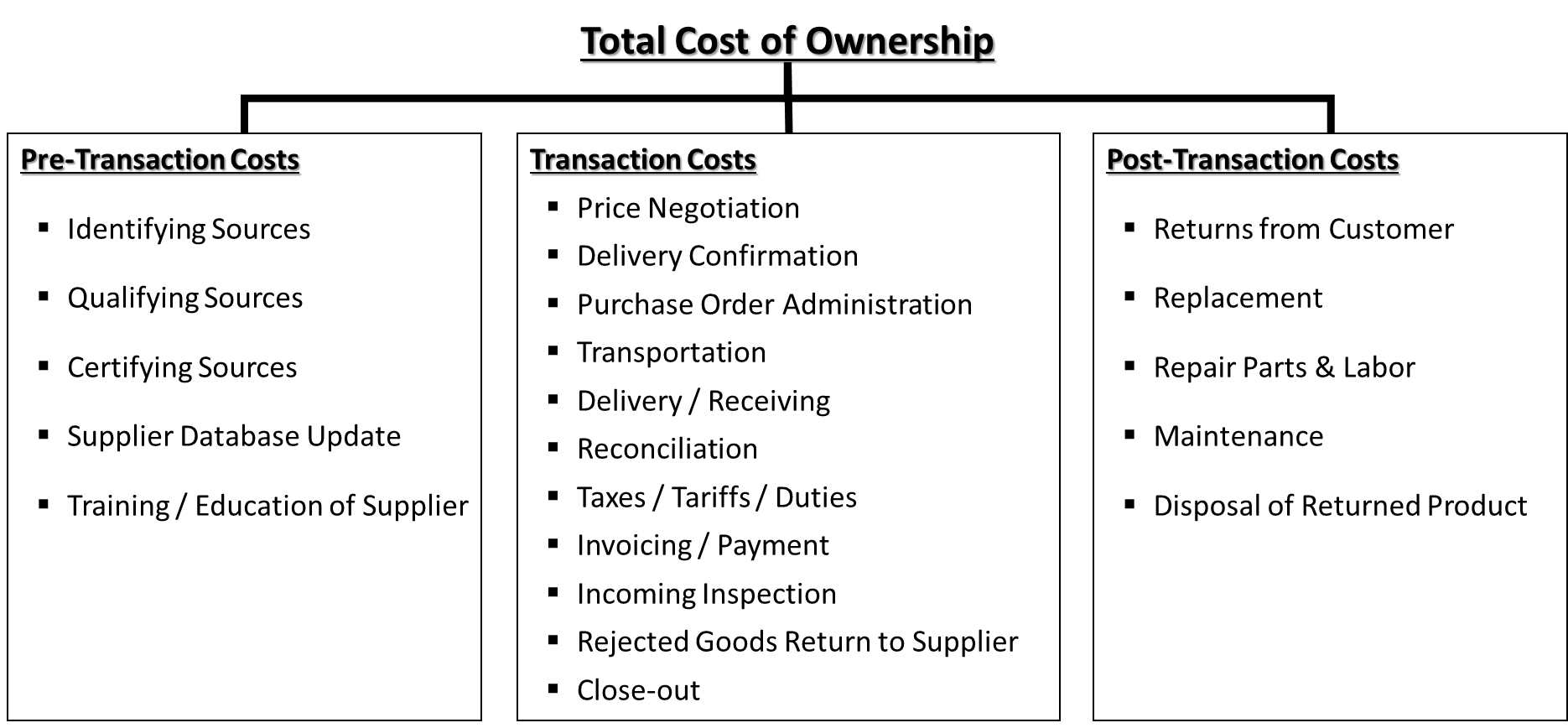

Components of the Total Cost of Ownership

- Pre-transaction costs - activities carried out prior to the actual buy and sell transaction

- Transaction costs - activities carried out as part of the actual buy and sell transaction

- Post-transaction costs - activities carried out following the actual buy and sell transaction

Make vs. Buy Decision

- Make vs. buy decision - “the act of deciding whether to produce an item internally or buy the item from an outside supplier”

- Make: producing (i.e., manufacturing) materials or products internally

- Buy/outsource: buying materials, components, or products

- Strategic decision

- Based on 3 key pillars

- Business strategy

- Risks

- Economic factors

Pillar 1 - Business Strategy

- Business strategy - includes the strategic importance to the company of the product or service that is being considered for outsourcing as well as the process, technologies, or skills required to make the product or deliver the service

- These factors must be considered in today’s environment and how they may change in the future

- It is desirable to choose in-house capabilities when a product or a function is critical to the company’s performance or is considered a core operation

Pillar 2 - Risks

- Risks - include lower quality reliability, and predictability of outsourced solutions as compared with in-house manufacturing or services as well as risks inherent in the process of identifying and selecting the right supplier and structuring a workable ongoing relationship

- When there are multiple suppliers, a single failure in the supply chain may not be fatal.

- When suppliers are making components rather than finished products, manufacturing errors will likely be caught during assembly and not be passed on to the consumer directly.

- Because outsourcing introduces such a wide array of new risks, companies must be keenly aware of any potential pitfalls with suppliers, and evaluate outsourcing partners based on their importance to the organization

Pillar 3 - Economic Factors

- Economic factors - include the impact of outsourcing on capital expenditures, return on invested capital, and return on assets, as well as the possible savings achieved through outsourcing

Make vs. Buy Decision

- It is important to analyze all of the relevant expenses associated with developing the capability to make a product, compared to all of the expenses associated with buying the product

- Key factors to be considered

- Qualitative factors - more subjective and include control over quality, the reliability and reputation of the potential suppliers (internal or external), and the impact of the decision on customers and suppliers

- Quantitative factors - incremental costs of either making or purchasing the item, such as the availability of manufacturing facilities, needed resources, and manufacturing capacity

Qualitative Reasons for Making

- Protect proprietary technology - You may not want your intellectual property to be out in the public domain

- No competent supplier - There may not be an existing supplier in the market and you may not want to spend the time or effort to develop one

- Control of lead-time - You may feel that you have more control over the lead time to produce the product than a supplier

- Use existing idle capacity - Make use of excess capacity by making a material instead of letting the capacity sit idle

- Better quality control - You may feel that you have more control of the quality of the material / product than a supplier

Quantitative Reasons for Making

- Overall lower cost - You may be able to produce the material or product at a lower cost and avoid paying a 3rd party's profit margin

- Control of transportation and warehousing costs - If you make an item in-house, you avoid transportation costs, and may be able to keep warehousing costs to a minimum

Qualitative Reasons for Buying/Outsourcing

- Non-strategic - if it is a non-strategic item

- Insufficient Capacity - a firm may be at or near capacity and subcontracting from a supplier may make better sense.

- Temporary Capacity Constraints - the concept of “extended workbench” which involves short-term supplementing internal capacity with external capacity during time of constraint or overloaded work centers.

- Lack of Expertise - firm may not have the necessary technology and expertise

- Quality - Suppliers may have better technology, process, & skilled labor

- Multi Sourcing Strategy - to achieve a multi sourcing strategy using an external supplier in addition to an internal source.

- Brand Strategy - take advantage of a supplier’s brand image, reputation, popularity, etc.

Quantitative Reasons for Buying/Outsourcing

- Cost advantage - suppliers may provide the benefit of economies of scale, especially for components that are non-vital to the organization’s operations

- Inventory considerations - opting to have the supplier hold inventory of the item or the materials required to produce the item

Benefits of Outsourcing

- Concentrate on core capabilities

- Reduce staffing levels

- Accelerate reengineering efforts

- Reduce internal management problems

- Improve manufacturing flexibility

Additional Make vs. Buy Concepts

- In-sourcing - reverting to in-house production when external quality, delivery, and services do not meet expectations

- Ex.: tech support

- Co-sourcing - 1.) the sharing of a process or function between internal staff and an external provider; 2.) using dedicated staff an an external provider that works exclusively under your control and direction

- Ex.: project-based consulting firm

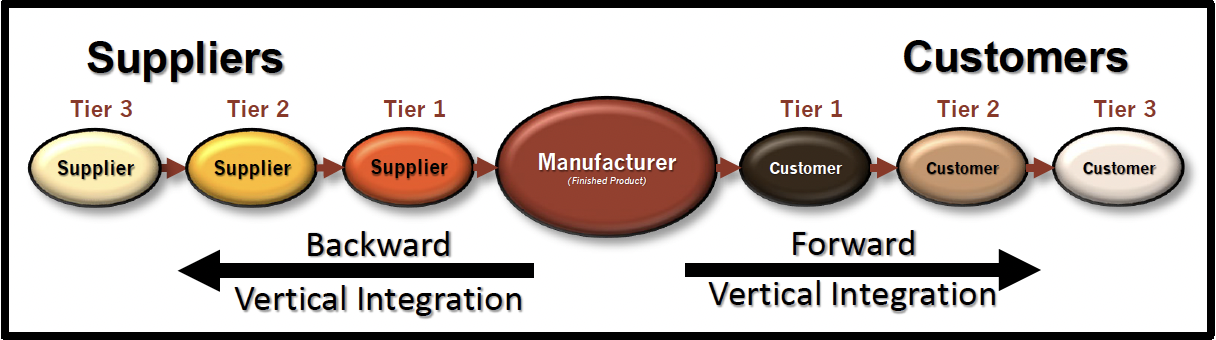

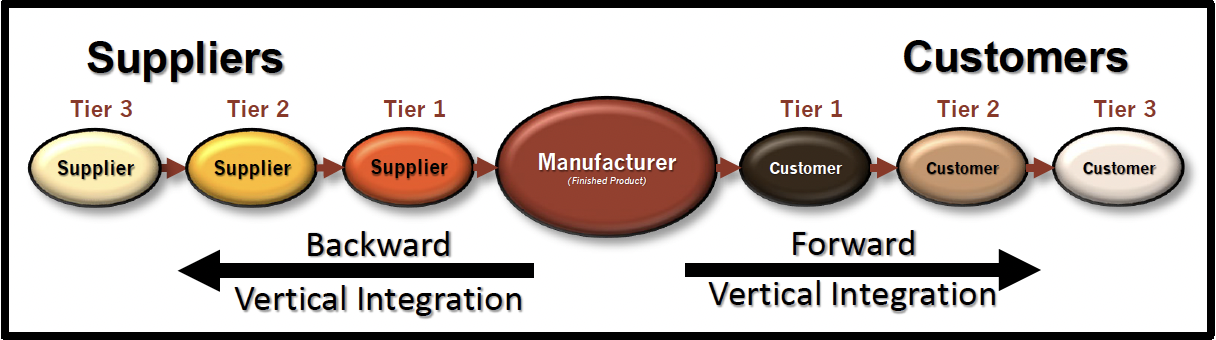

Other Types of Make/Buy Strategic Decisions

- Backward vertical integration - a company acquires one or more of their suppliers

- Ex.: a manufacturer buying the key supplier of a critical material to make ownership of this aspect of their supply chain

- Forward vertical integration - a company acquiring one or more of their customers

- Ex.: a manufacturer buying a wholesaler/distributor to take ownership of this aspect of their supply chain

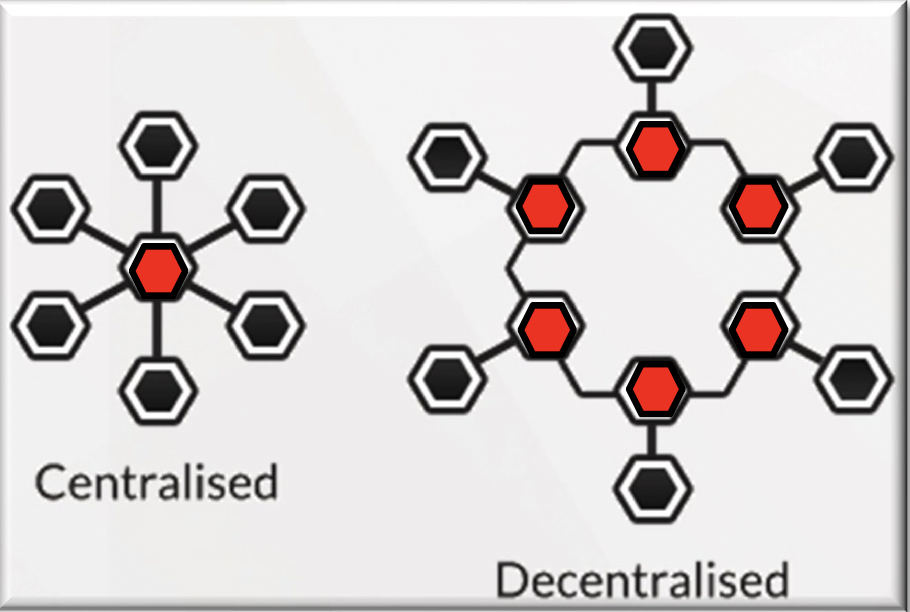

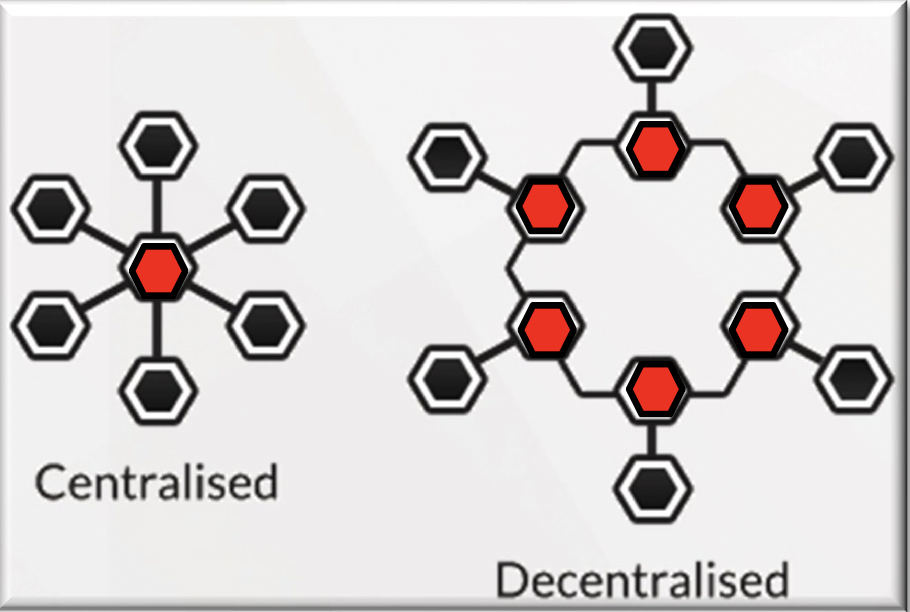

Centralized vs. Decentralized Purchasing

- Purchasing organization - dependent on many factors, such as market conditions and types of materials required

- Centralized purchasing - purchasing department located at the firm’s corporate office makes all the purchasing decisions

- Decentralized purchasing - individual, local purchasing departments, such as at the plant level, making their own purchasing decisions

- Hybrid approach (centralized/decentralized purchasing) - centralized purchasing for products and services used throughout the corporation. Decentralized purchasing for products and services used only locally at each facility

- Center led - strategic aspects done at upper levels (centralized); tactical aspects done at lowest level (decentralized)

Advantages of Centralization

- Concentrated volume

- Leveraging purchase volume

- Avoiding duplication

- Specialization

- Lower transportation costs

- No competition within units

- Common supply base

Advantages of Decentralization

- Knowledge of local requirements

- Local sourcing

- Less bureaucracy

International Purchasing

Reasons for Global Sourcing

- The opportunity to improve quality, cost, and delivery performance

- To exploit global efficiencies

- Access to low cost labor and materials

- Take advantage of tax breaks and low trade tariffs

- To respond to insufficient domestic capacity

- To achieve access to better process and product technology

- Due to a change in the domestic business environment

- To take advantage of reciprocal trade and countertrade arrangements

Specialized Knowledge

- Companies interested in pursuing international purchasing arrangements must acquire some specialized knowledge particular to buying products and services internationally.

- This specialized knowledge includes aspects of:

- Tariffs - duties, taxes, or customs imposed by the host country for imported or exported goods

- Non-tariff barriers - quotas, licensing agreements, embargoes, laws and regulations imposed on imports and exports

- Know tariffs and non-tariff barriers

- Countertrade - international trade by exchange of goods rather than by currency

Service Providers

- Companies can choose to use service providers that already have the specialized skills and knowledge necessary to deal with international purchasing issues and challenges

- Some entities offering these specialized skills and knowledge:

- Import Brokers - Agents licensed by the governmental regulatory authority to conduct business on behalf of importers, for a service fee

- They take the burden of filling out import paperwork, and clearing products through customs barriers for importers

- Import Merchants - A person or company engaged in the purchase and sale of imported commodities for profit

- They buy and take title to the goods being imported and then sell the goods domestically

- Trading Companies - Buy products in one country and sell them in different countries where they have their own distribution network

- They mostly work with high production volume products such as raw materials, chemicals, etc. They may carry a wide variety of goods (such as from a catalog)

- Import Brokers - Agents licensed by the governmental regulatory authority to conduct business on behalf of importers, for a service fee

Government and Non-profit Purchasing

Terms

- Bid - a proposal or quotation submitted in response to a solicitation from a contracting authority

- Sealed bid - enclosed in a sealed envelope and submitted in response to an invitation to bid

- Competitive bidding - a procurement process in which bids from competing suppliers, for the right to supply specified materials or services, are requested

- This process is generally initiated by advertising the scope, specifications, and terms and conditions of the proposed contract as well as the criteria by which the bids will be evaluated, either openly or to a selected group of potential bidders

Competitive Bidding

- Competitive bidding aims at obtaining goods and services at the lowest prices by stimulating competition, and by preventing favoritism.

- Open competitive bidding-the sealed bids are opened in full view of all who may wish to witness the bid opening

- Closed competitive bidding-the sealed bids are opened in presence only of authorized personnel.

- The competitive bidding process does not allow for negotiations. By law, the contract is awarded to the lowest priced responsive and responsible bidder

Bonds

- Bidders are generally required to furnish bonds as an incentive to ensure that the successful bidder will fulfill the contract awarded

- Bid bond - a debt secured by a bidder for the purpose of providing a guarantee that the successful bidder will accept the contract once awarded. If not, the bond would be forfeited

- Performance bond - a debt secured by a bidder for the purpose of providing a guarantee that the work will be on time and meet specifications

- Payment bond - a debt secured by a bidder for the purpose of providing protection against 3rd party liens not fulfilled by bidder

Assessing and Improving the Purchasing Function

- The purchasing function is one of the most value-enhancing functions in any organization

- It is preferable to periodically monitor the purchasing function’s performance against set standards, goals, and/or industry benchmarks

- Surveys or audits can be administered as self-assessments among purchasing staff as part of the annual evaluation process

Benchmarking Successful Sourcing Practices

- Benchmarking - a process of measuring the performance of a company's products, services, or processes against those of another business considered to be the best in the industry, aka “best in class”

- Point is to identify internal opportunities for improvement

Chapter 6: Strategic Sourcing

What is Strategic Sourcing, Drivers, and Objectives

What is strategic sourcing?

- Sourcing - the process of identifying a company that provides a needed good or service

- Strategic sourcing - a comprehensive approach for locating and sourcing key suppliers, so that an organization can leverage its consolidated purchasing power to find the best possible values in the marketplace

- Requires analysis of what an organization buys, from whom, at what price, and at what volume

- Emphasis is placed on the entire life-cycle of a product, not just its initial purchase price

- In today’s competitive business climate, supply chain management professionals are constantly seeking out creative ways to reduce costs, improve the quality of the final product and achieve a faster time to market

- Time to market - measures the time on the calendar (months or years) it takes to bring a concept to market

- How it works

- Identifying suppliers

- Cultivating relationships

- Continuously improving skills

- Understanding and embracing the possibilities

Identifying Suppliers

- Effective procurement managers consistently locate the best quality materials at the lowest possible cost from the most reliable suppliers

Understanding and Embracing the Possibilities

- Some of the top competencies needed to excel in making the most of a company’s strategic sourcing decision-making process include:

- Recognizing and accessing key issues, opportunities, strategies, and techniques to achieve a competitive advantage

- Identifying internal and external challenges that affect sourcing strategy

- Defining issues involved in global sourcing, electronic procurement, negotiations, and ethics

- Applying problem-solving skills to determine the best course of action pertaining to the above strategy areas

Objectives of Strategic Sourcing

- Objectives of strategic sourcing involve the reduction of cost while maintaining or improving quality:

- Improve the value‐to‐price relationship

- i.e. achieve cost reductions while maintaining or improving quality/service

- Understand the category buying and management process to identify improvement opportunities

- Examine supplier relationships across the entire organization. Share best practices across the organization

- Develop and implement multi‐year contracts with standardized terms and conditions across the organization

- Leverage the entire organization’s spend

- Improve the value‐to‐price relationship

Developing Successful Sourcing Strategies

Sourcing Strategies

- Analysis and ability to make adjustments based on price, evaluation of supplier performance, and the overall needs of the organization

- High-level sourcing strategies include:

- Insourcing - producing goods or services using a company’s own internal resources

- Outsourcing - the traditional definition involves purchasing an item or service externally, which had been produced using a company’s own internal resources previously

- Recently: term has become synonymous with the concept of buying an item from an external supplier regardless of whether the item had previously been produced internally

- Single-source - a sourcing strategy where there are multiple potential suppliers available for a product or service, but the company decides to purchase from only one supplier

- Multi-source - purchasing a good or service from more than one supplier. Companies may use multi-sourcing to create competition between suppliers in order to achieve higher quality and lower price

- A regular review of an organization’s sourcing strategy is a must in order to achieve significant agreed upon results

- How many suppliers do you need?

- Current trends favor using fewer sources

- HOWEVER, single-source is risky

- Current trends favor using fewer sources

- Reasons for single supplier

- To establish a good relationship

- Less quality of variability

- Lower cost

- Transportation economies

- Proprietary product or process

- Volume too small to split

- Reasons for multiple suppliers

- Need more capacity

- Spread risk of supply disruption

- Create competition

- More sources of information

- Dealing with special kinds of business

- Successful sourcing strategies are almost always different for functional products vs. innovative products

- Functional products - MRO items and other commonly low profit margin items with relatively stable demands and high levels of competition

- Ex.: office supplies, food staples

- Potential strategy: reliable, low cost multi-sourced suppliers

- Innovative products - characterized by short product life cycles, volatile demand, high profit margins, and relatively less competition

- Ex.: technology products such as iPhone

- Potential strategy: innovative, high-tech, cutting edge, market leading single-sourced supplier. Long-term partnership.

- Functional products - MRO items and other commonly low profit margin items with relatively stable demands and high levels of competition

Framework for Sourcing Strategy Development

- The strategic sourcing process requires an organized approach that allows the organization to systematically work on spend areas or processes that can result in cost saving benefits

- Essential steps:

- Identify the targeted spend area

- Create the sourcing team

- Develop a team strategy and communication plan

- Gather market information

- Develop a supplier portfolio

- Develop a future state

- Select suppliers and negotiate

- Implement Supplier Relationship Management (SRM)

Spend Analysis

- Spend analysis - consists of categorizing and analyzing expenditure data for the purpose of decreasing costs, improving efficiency, and monitoring compliance

- Basic steps for conducting a spend analysis:

- Defining the scope

- Ex.: expenditures over a specified period

- Identify all data sources

- Gathering and consolidating all the data into one database

- Cleansing the data (i.e., correcting errors) and standardizing it for easy review

- Categorizing the data

- Ex.: commodity and sub-commodities

- Analyzing the data for:

- Best deals per supplier

- To ensure that all purchases are from preferred suppliers

- To reduce the number of suppliers per category

- Repeat the process on a regular basis

- Defining the scope

- Key areas of a typical spend analysis:

- Total historic expenditures and volumes

- Future demand projections or budgets

- Expenditures categorized by commodity and sub-commodity

- Expenditures by division, department, or user

- Expenditures by supplier

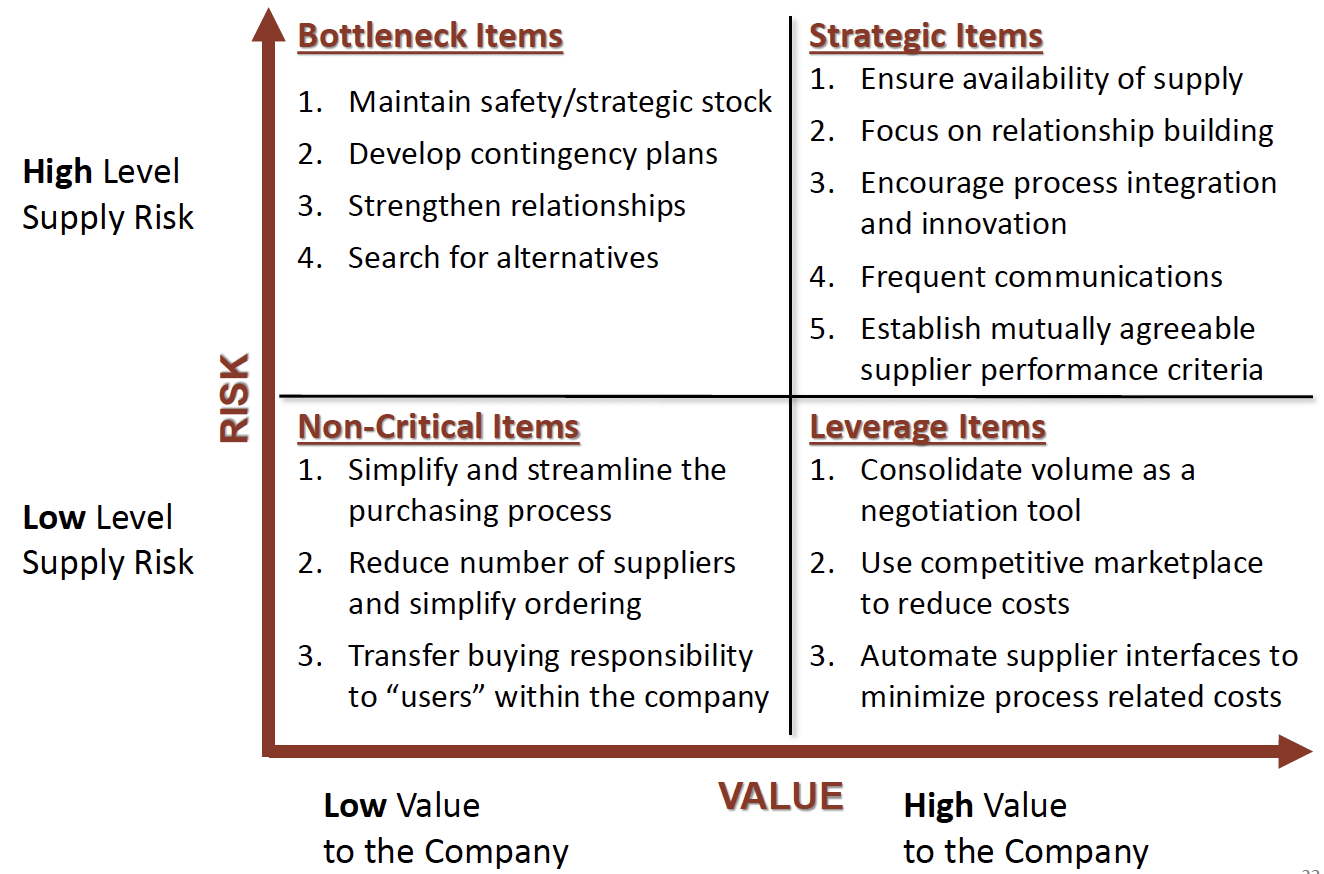

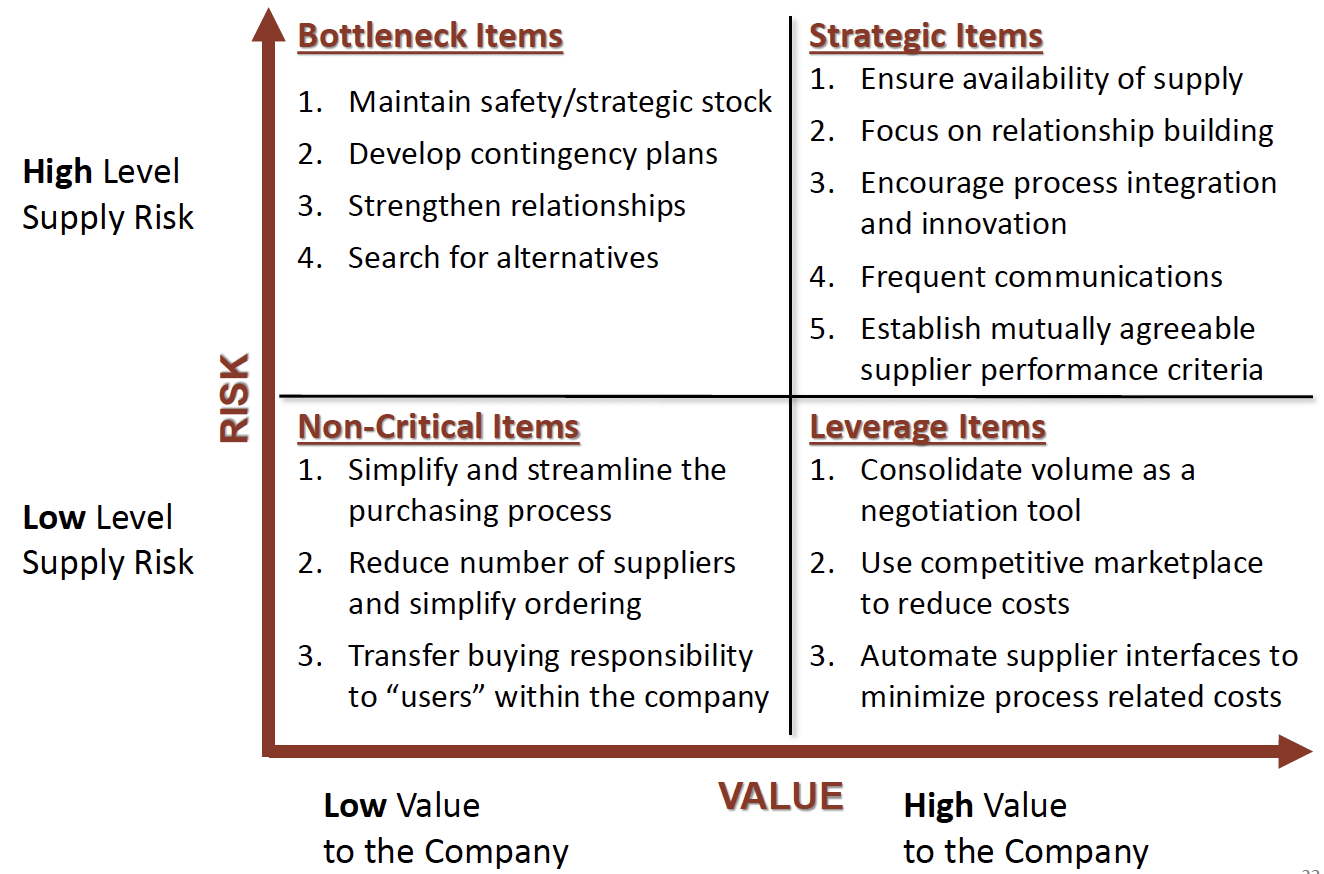

Sourcing Categories

General Sourcing Categories

- Non-critical - routine items that involve a low percentage of the firm’s total spend and involve very little supply risk

- Ex.: standard screws in a computer factory

- Bottleneck - unique procurement problems. Supply risk is high and availability is low. Small number of alternative suppliers

- Ex.: an integral part of technology hardware, power pack for a laptop

- Leverage - commodity items where many alternatives of supply exist, and supply risk is low. Spend is high and there are potential procurement savings

- Ex.: plastic or raw materials for Lego bricks

- Strategic - strategic items and services that involve a high level of expenditure and are vital to the firm’s success

Sourcing Strategies by Category - Kraljic Model

Examples of Sourcing Categories

Supplier Base and Selection

Supplier Base

- Supply base - the group of suppliers from which a company acquires goods and services

- Supply base rationalization (aka supply base reduction/optimization) - reduction in the supply base to the lowest number of suppliers possible without significantly increasing risk

- Firms emphasize long-term strategic supplier alliances consolidating volume into one or fewer suppliers, resulting in a smaller supply base

- Buyer-supplier partnerships are easier to manage with a rationalized supply base, and they can result in:

- Reduced purchase prices

- Fewer supplier management problems

- Greater levels of quality and delivery reliability

- Closer and more frequent interaction between buyer and supplier

Supplier Selection

- Supplier selection - typically conducted by a cross functional team

- Commonly used criteria for selecting suppliers using evaluation forms or scorecards:

- Cost

- Quality

- Capacity

- Service

- Location

- Reliability

- Communication capability

- Order system and cycle time

- Willingness to share information

- Product and process technologies

- Sample scorecard

Use of AI in Supplier Selection

- AI can improve supplier selection and increase the effectiveness of supplier relationship management

- Supplier-related risks are a major consideration for supply chain professionals

- A supplier’s single mistake can significantly damage a company’s reputation

- AI can quickly and thoroughly analyze supplier-related data such as on-time in-full delivery performance, audits, evaluations, and credit scoring and provide information to use for future decisions regarding certain suppliers

- Thus, a company can make better supplier decisions and improve its customer service

Preferred Suppliers

- Preferred suppliers - those that best met your company’s overall purchasing requirements

- “Supplier of choice”

- Achieved a specific and exceptional level of performance over time as measured by a set of criteria agreed upon by both buyer and supplier

- Typically, trusted partners who know the buyer’s organization, processes, procedures, and requirements

- Provide a higher value than their competitors and are characterized as reliable, responsive, flexible, and cost effective

- Preferred suppliers provide:

- Product and process technology and expertise

- Product development and value analysis

- Information on latest trends in materials, processes, or designs

- Capacity for meeting unexpected demand

- Cost efficiency due to economies of scale

Strategic Alliance Development

Strategic Alliance

- Strategic alliance - in sourcing is an agreement between a buyer and a supplier to pursue some agreed upon objectives while remaining independent organizations

- Companies agree to share information and resources to achieve a mutual benefit

- Preferred supplies are potentially ideal candidates for a strategic alliance

- Benefits

- Potential to increase revenue and profits for both parties

- Potential to create a competitive advantage or block a competitor from gaining market share

- Mitigate risks and ensure a continuity of supply

- Position the partners for future strategic opportunities

Strategic Alliance Development

- Strategic alliance development - an extension of supplier development which refers to increasing a key or strategic supplier’s capabilities

- Results in better market penetration, access to new technologies and knowledge, and a higher return on investment

- Eventually extends to a firm’s second-tier suppliers as the firm’s key suppliers begin to form their own alliances

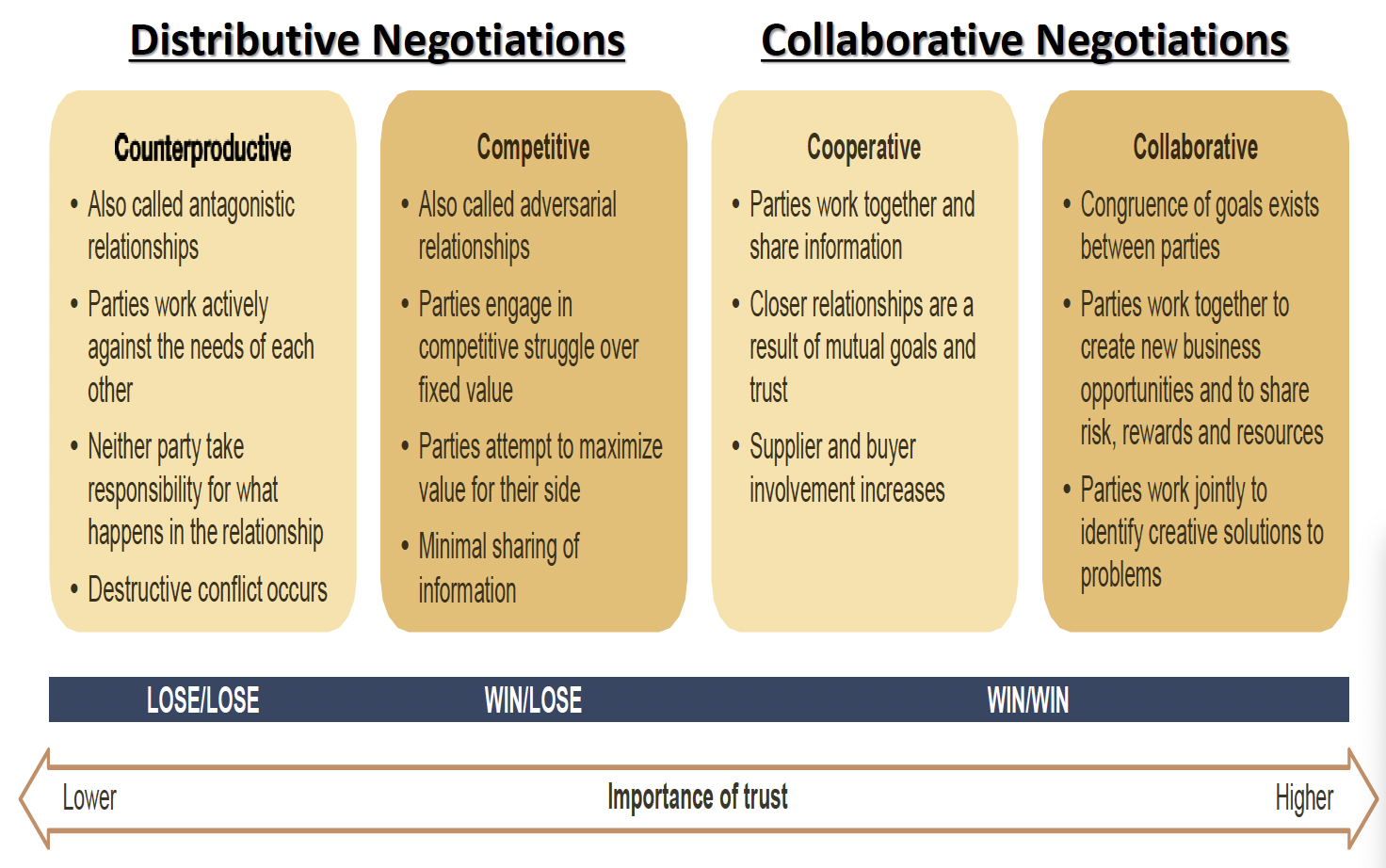

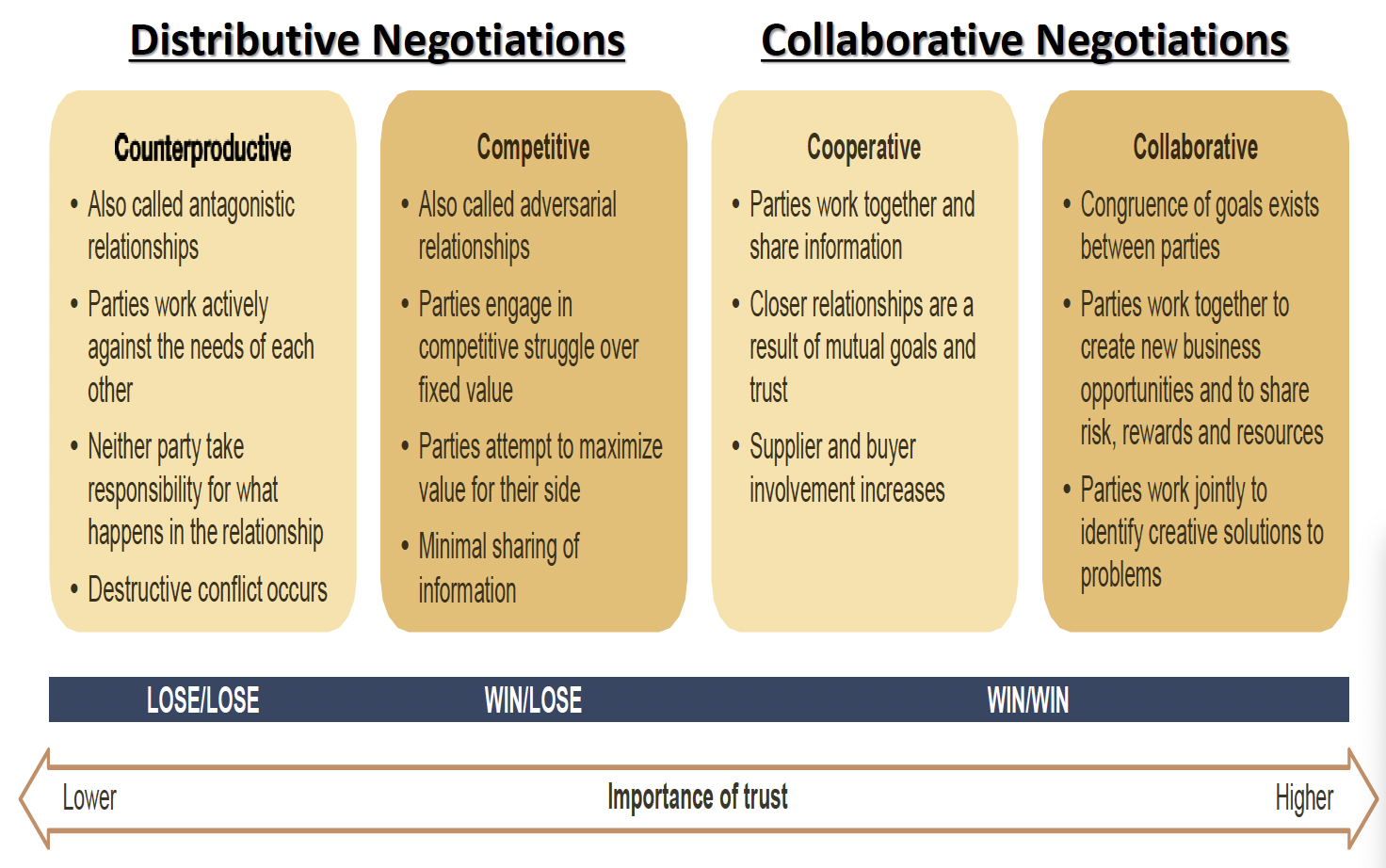

Negotiating Win-Win Strategic Alliance Agreements

- Distributive negotiations - a process that leads to self-interested, one-sided outcome

- Collaborative negotiations - both sides work together to maximize the outcome or create a win-win result

- Requires open discussions and a free-flow of information between parties

- Successful collaborative negotiations start with a clearly expressed understanding of how each company wants to benefit from the collaboration

- Alignment between parties regarding motivation, contribution, financial benefit, and the management of the alliance are essential.

- Negotiations are not about each company obtaining the most value, negotiations are more about establishing a relationship that works well for both parties

Continuum of Buyer-Supplier Relationships

- Distributive negotiations

- Counterproductive and competitive

- Collaborative negotiations

- Cooperative and collaborative

Additional Sourcing Concepts

Reverse Auctions

- Reverse auction - a sourcing technique where pre-qualified suppliers enter a website at a predesignated time and date and try to underbid competitors to win the buyer’s business

- Sellers bid against one another to secure the buyer’s business, driving the price to be paid for the item downward

- Bid prices are monitored until the session is officially over. The winning bidder is the seller who offers the lowest price

- Used by private companies, public sector agencies, and non-profit organizations

Vendor Managed Inventory

- Vendor managed inventory (VMI) - suppliers directly manage buyer inventories to reduce the buyer’s inventory carrying costs and avoid stockouts for the buyer

- From buyer-firm’s perspective:

- Supplier tracks inventories

- Supplier determines delivery schedules and order quantities

- Buyer can take ownership at the stocking location

- Buyer may also be able to avoid taking ownership until the material is actually being used

- From supplier’s perspective:

- Avoids ill-advised customer orders

- Supplier decides inventory set up and shipments

- Opportunity for supplier to educate customers about other products

Co-managed Inventory

- Co-managed inventory (CMI) - an arrangement where a specific quantity of an item is stored at the buyer’s location

- Once it is used, the item is replaced by the supplier with the full knowledge and approval of the buyer

- The buyer provides systems access to the supplier, and the supplier takes responsibility for managing the replenishment process in the buyer’s system

- The supplier reviews all of the available information and generates orders in the buyer’s system.

- The primary difference from VMI is that in CMI the supplier is just recommending an order which is not confirmed until and unless the buyer approves it

Supplier Co-location

- Supplier co-location - very similar to VMI and CMI except that a representative of the supplier is actually embedded in the buyer’s purchasing group to forecast demand, monitor inventory, and place orders

- The employee is on the payroll of the supplier but works for the buyer and is empowered to forecast demand, monitor inventory, and place orders

- The arrangement involves the buyer granting the supplier access to potentially proprietary or sensitive data.

- Benefits both buyers and suppliers, from day-to-day operational improvement, to strategic advances in the structure of the supply chain organization

Ethics and Sustainability

Business Ethics and Ethical Sourcing

- Most companies today have some type of Corporate Social Responsibility program

- Programs frequently require suppliers to agree to abide by a Supplier Code of Conduct to be considered an approved supplier

- Corporate social responsibility (CSR) - the practice of business ethics

- Business ethics - the application of ethical principles to business

- 2 main ethical approaches

- Utilitarianism - an ethical act is one that creates the greatest good for the greatest number of people and should be the guiding principle of conduct

- Rights and duties - some actions are just right in and of themselves, regardless of the consequences. Do the right thing!

- 2 main ethical approaches

Business Ethics and Ethical Sourcing

- Ethical sourcing - that which attempts to take into account the public consequences of organizational buying, or to bring about positive social change through organizational buying behavior

- Involves the procurement organization ensuring that the products being sourced are acquired in a responsible and sustainable manner

- The people involved in production should be treated fairly and work in a safe environment

- Environmental and societal impacts must be considered

Chapter 7: Supplier Relationship Management

What is Supplier Relationship Management (SRM)

- Supplier relationship management (SRM) - the discipline of strategically planning for, and managing, all interactions with the third party organizations that supply goods or services to an organization to maximize the value of those interactions

- Most procurement professionals view SRM as an organized approach to defining what they need and want from a select group of key suppliers

- Establishing and managing the company-to-company link to obtain those needs

- SRM is often part of the rollout of Strategic Sourcing

- Best supplier candidate traits:

- Providing high volumes of a product/service

- Providing lesser quantities of a crucial product/service

- That serve many business units of a company or organization

- Where intensive engineering, manufacturing and/or logistic interaction is essential

Keys to Successful Strategic Partnerships

Strong Supplier Partnerships

- Important to achieving win-win competitive performance for the buyer and supplier

- Require a strategic perspective as opposed to a tactical one

- Involves “a mutual commitment over an extended time to work together to the mutual benefit of both parties, sharing relevant information and the risks and rewards of the relationship”

10 Keys to developing Successful Strategic Partnerships:

- Building trust

- Having a shared vision and objectives

- Developing personal relationships

- Establishing mutual benefits and needs

- Gaining commitment from top management

- Managing change

- Information sharing and lines of communication

- Understanding and influencing capabilities

- Continuous improvement

- Measuring performance

Building Trust

- With trust, partners are more willing to work together, find compromise solutions to problems, work toward achieving long-term benefits for both parties, and go the extra mile

- Trust is earned

- Also easily lost and almost impossible to regain

Shared Vision and Objectives

- Both partners must share the same vision and have objectives that are not only clear but mutually agreeable.

- The focus must move beyond tactical issues and toward a more strategic path to corporate success.

Personal Relationships

- Strategic Partnerships begin with the development of personal relationships between key people at each company.

- It is people who communicate and make things happen

Mutual Benefits and Needs

- Partnership should result in a win-win situation, which can only be achieved if both companies have compatible needs

- An alliance is much like a marriage, and if only one party is happy, then the marriage (i.e., alliance) is not likely to last

Commitment from Top Management to Support the Strategic Parternship

- Commitment must start at the highest management level.

- Partnerships tend to be successful when top executives are actively supporting the partnership

Managing Change

- Companies must be prepared to manage change that comes with the formation of new partnerships

Information Sharing and Establishing Lines of Communication

- Both formal and informal lines of communication should be set up to facilitate the free flow of information

Understanding Capabilities

- Key suppliers must have the right technologies and capabilities to meet cost, quality, and delivery requirements in a timely manner

Continuous Improvement

- Making a series of small improvements over time results in the elimination of waste in a system

- Buyers and suppliers must be willing to continuously improve their capabilities in meeting customer requirements

- Common Process: Plan, Do, Check, Act

- Plan - identify each specific improvement that is needed, what change is necessary to make the improvement, and then plan for that change

- Do - implement the change on a small scale to see if the change improves the process before moving forward with a full implementation

- Check - use data to analyze the results to see if the change made a positive impact

- Act - if the change was successful, implement the change on a wider scale and continuously assess your results. If the change did not work, then the root cause was most likely not identified, or the change was not the correct solution, and you may need to begin the cycle over again

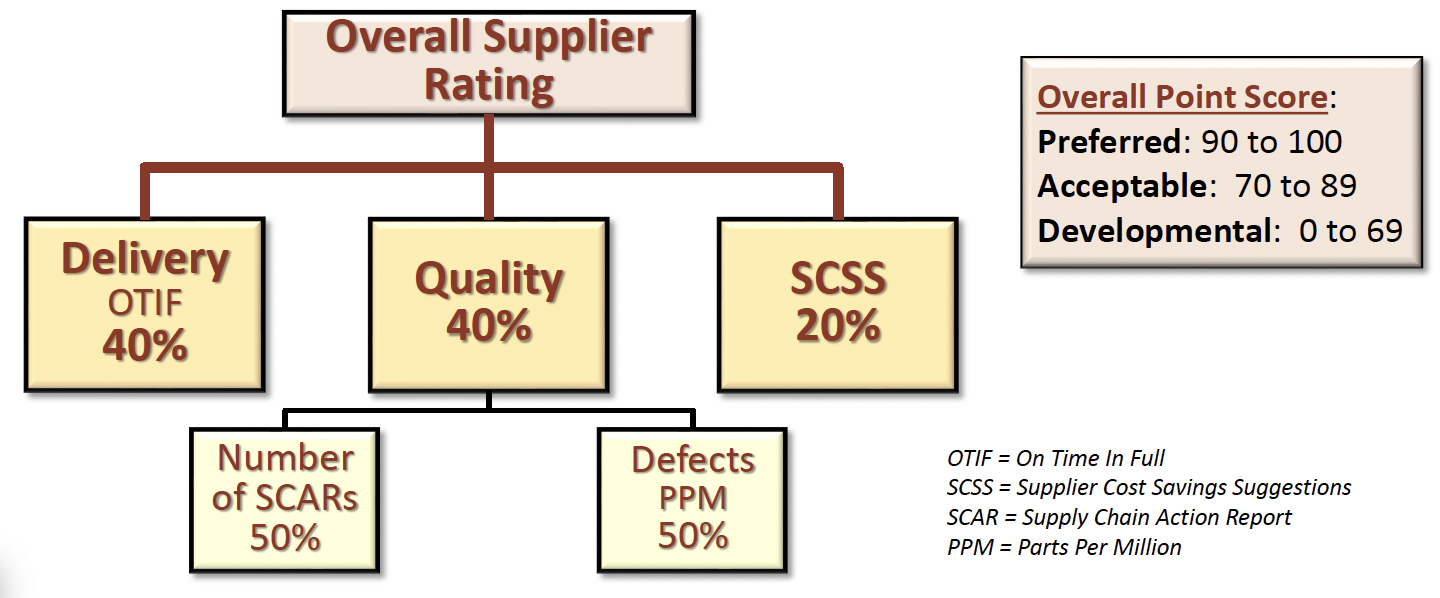

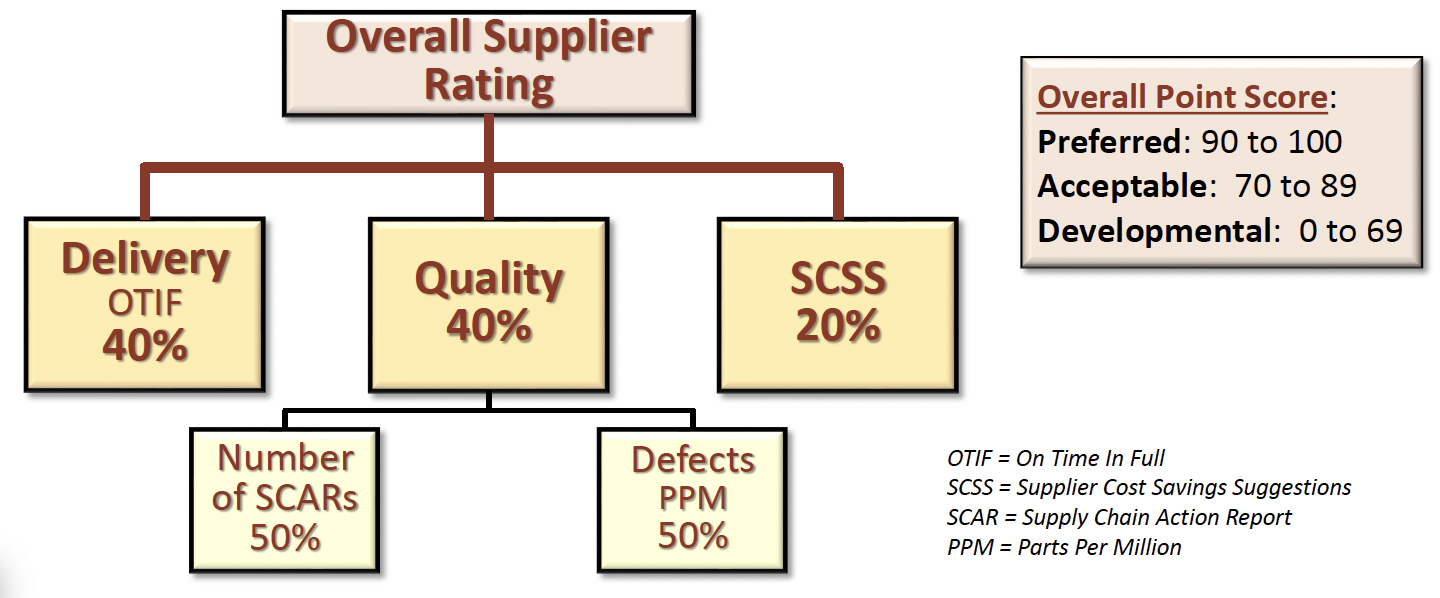

Measuring Performance

- You can’t improve what you don’t measure

- Measures related to quality, cost, delivery, and flexibility are used to evaluate suppliers

- Metrics should be:

- understandable

- easy to measure,

- focused on real value-added results [S.M.A.R.T. objectives]

- Specific

- Measurable

- Achievable

- Relevant

- Time-oriented

- A multi-criteria approach is best [i.e., a SCORECARD]

- Total cost of ownership - made up of all costs associated with the acquisition, use, and maintenance of a good or service

Benefits of Strategic Partnerships with Suppliers

- Benefits for buyers

- Increased operating efficiencies

- Lower costs

- Enhanced service

- Incremental revenue

- Improved quality

- Preferred access to the supplier’s best people

- Influence over supplier investments and technology

- Preferred access to supplier ideas

- Increased innovation from and with suppliers

- Sustainable competitive advantage

- Increased operating efficiencies

- Benefits for suppliers

- Increased operating efficiencies

- Lower cost of sales

- Increased margins

- Incremental revenue

- Greater visibility into buyer’s purchasing plans

- Increased scope of business

- Opportunities to develop, pilot, and showcase innovative solutions

- Longer term buyer commitments; greater predictability of future business

- Sustainable competitive advantage

- Increased operating efficiencies

Supplier Evaluation

- Supplier evaluation - a process to identify the best and most reliable suppliers

- Sourcing decisions are made on facts and not on perception (through the use of defined criteria)

- Frequent feedback can help avoid surprises and maintain good relationships

- Hold regular review meetings

- Suppliers should be allowed to provide constructive feedback to the customer

Performance

- It is important to actively monitor a supplier’s performance and provide visibility and feedback on supplier performance at each stage of the evaluation process

- Some relevant metrics:

- Price and cost performance

- Product quality

- Delivery performance

- Contractual compliance

- Participation in product development initiatives

- Cooperativeness in third-party production management

- Support of ethics and sustainable practices

Evaluating and Selecting Key Suppliers

- Having a robust Supplier Evaluation process to select key suppliers with whom to develop a collaborative relationship → purchase cost becomes relatively less important

- Assumption: excellent suppliers will be able to drive costs out

- “Squeezing” suppliers to generate a lower annual purchasing spend hurts strategic relationships!

- Unfortunately, it is often still done! [Profit Leverage Effect]

- Key supplier selection - typically conducted by a cross-functional team using evaluation forms or scorecards

- Weighting techniques often used

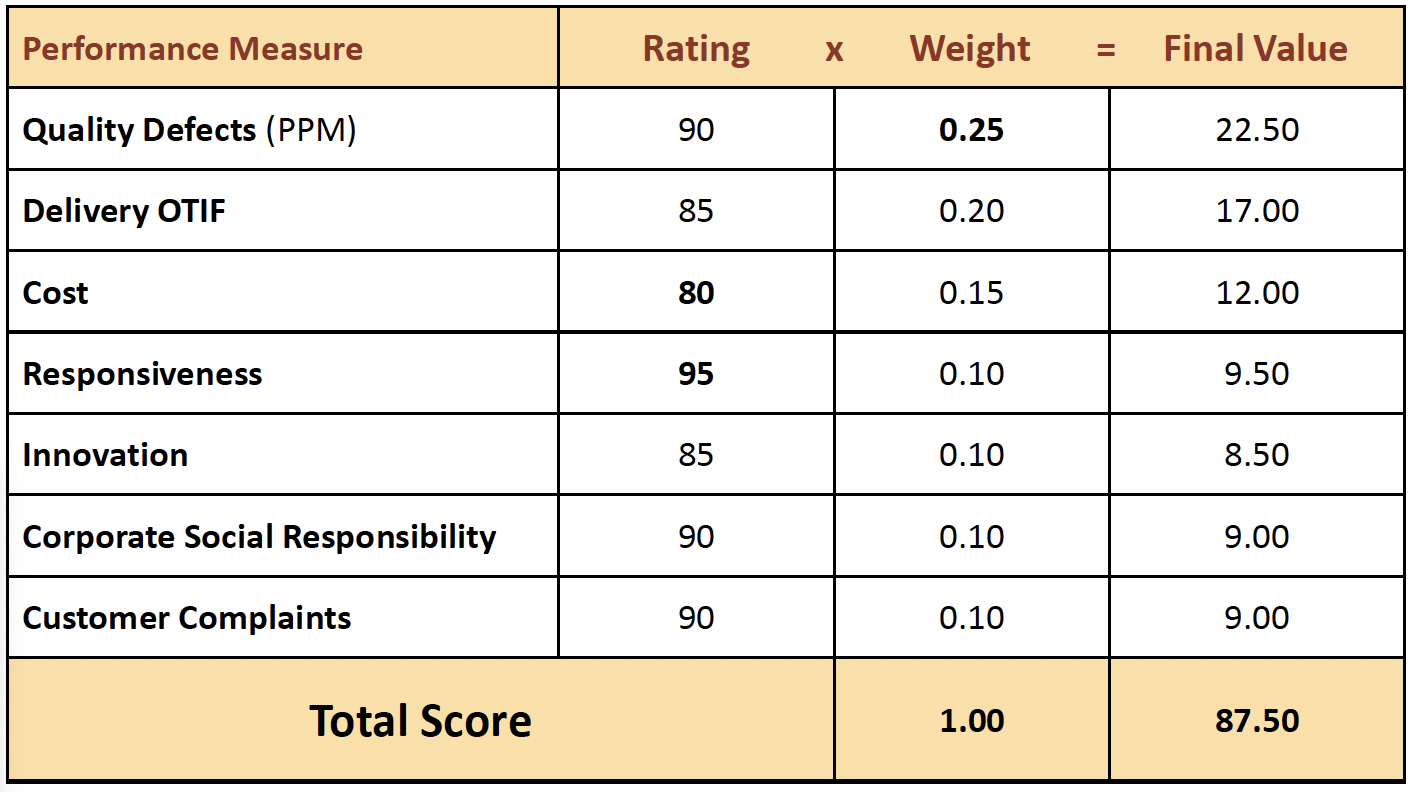

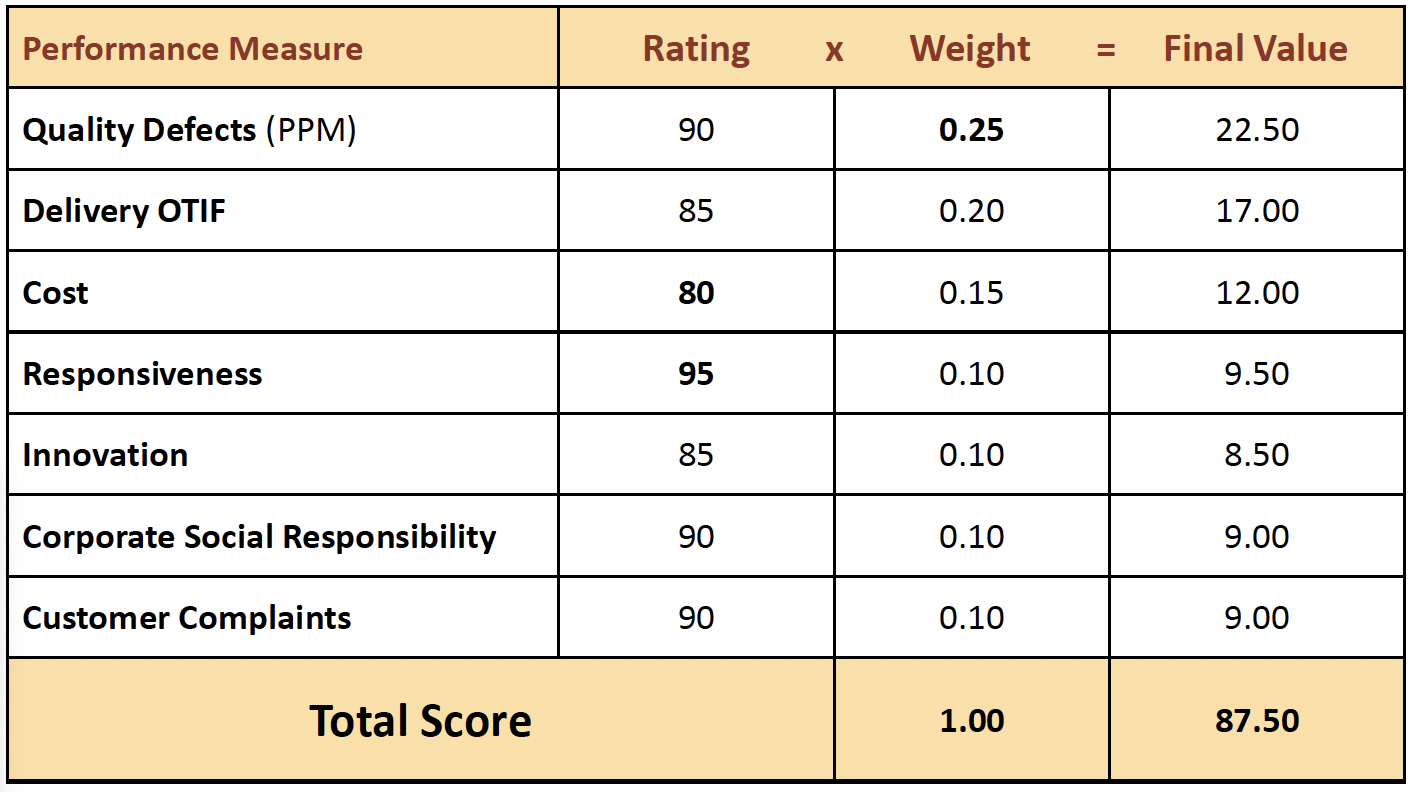

Weighted-Criteria Evaluation System

- Select the key dimensions of performance mutually acceptable to both buyer and supplier

- Monitor and collect performance data

- Assign weights to each of the dimensions

- Evaluate performance measures between 0 and 100

- Multiply dimension rating by weight and sum of overall score

- Classify suppliers based on their overall score

- e.g., certified, preferred, acceptable, conditional, developmental, unacceptable, etc.

- Audit and perform ongoing certification review

- Example

- Preferred: work with these suppliers in maintaining a competitive position and on new product development

- Acceptable: require a plan from these suppliers outlining how they will achieve preferred status

- Developmental: require corrective actions from these suppliers on how they will achieve acceptable level. Look for alternative suppliers if these do not achieve acceptability within a fixed timeframe (e.g., 3 months)

- Supplier scorecard example

Supplier Certification

Supplier Certification Programs

- One element for building a strong strategic supplier partnership is having a well-defined and established Supplier Certification Program

- A certified supplier is a source that through prior experience and qualification can provide material of such quality that it needs little if any receiving inspection or testing before going into approved stock or into the product process

- Administration of a Certified Supplier Program requires planning and long-term attention

Benefits of Supplier Certification Programs

- Reducing the amount of time and labor required for the buyer to conduct incoming inspections of products and materials from certified suppliers, creates cost savings

- Buyer trains supplier on approved test methods so that supplier can test product before shipment, and provide a Certificate of Analysis (COA)

- Buyers may then opt to only test items periodically on incoming inspection rather than with each delivery or lot, providing that the periodic testing confirms the supplier’s results

- Building long-term relationships

- Recognizing excellence

- Decreasing the supplier base

- Certified suppliers are more reliable and therefore, you don’t need as may suppliers

Supplier Certification

- Supplier Certification programs are also used as verification that select suppliers operate, maintain, improve, and document effect procedures that relate to the buyer’s requirements for supply elements such as cost, quality, delivery, flexibility, etc.

- Can be used to help differentiate one supplier from another, and may be used to identify strategic supplier alliance candidates.

- As part of their overall certification process, companies may develop internal certification programs, and/or require external certifications from an organization such as the International Organization for Standardization (ISO)

Internal Certification Programs

- Example of criteria used for an internal certification program

- Supplier has no incoming product rejections for a specified time period.

- Supplier has no incoming late deliveries for a specified time period

- Supplier has no significant negative quality related incidents for a specified time period

- Supplier is ISO 9000 certified or has successfully passed a recent on-site quality system evaluation

- Supplier consistently meets a mutually agreed-upon set of clearly specified quality performance measures

- Supplier has a fully documented process and quality system with cost controls and continuous improvement capabilities

- Supplier’s processes are determined to be stable and in control

External Certification

- International Organization for Standardization (ISO) - the world's largest developer of voluntary international standards; it represents achieving and maintaining a standard of excellence verified by an independent third party organization.

- Benefits of ISO Certification:

- Greater market potential

- Compliance to procurement bids

- Improved efficiency and cost savings

- Higher level of customer service

- Heightened staff morale and motivation

- 2 commonly used ISO standards for supplier certification:

- ISO 9000 - a series of management and quality standards in design, development, production, installation, and service

- Companies wanting to sell in global market seek this certification

- ISO 14000 - a family of standards for environmental management

- Benefits: reduced energy consumption, environmental liability, waste and pollution, and improved community goodwill

- ISO 9000 - a series of management and quality standards in design, development, production, installation, and service

ISO 9000

- 8 quality management principles on which the ISO 9000 series quality management system standards are based on:

- Customer focus – understand current and future customer needs

- Leadership – establish unity of purpose and direction of the organization

- Involvement of people – people are the essence of an organization

- Process approach – a desired result is achieved through a managed process

- Systems approach to management – managing interrelated processes

- Continual improvement – performance improvement is a permanent objective

- Factual approach to decision making – decision are based on facts and data

- Mutually beneficial supplier relationship – interdependent benefits create value for both an organization and its suppliers.

External Certification

- ISO certified suppliers are preferred by procurement departments because

- They have to conform to an externally defined set of standards for quality and delivery of service

- They are easier for procurement to initially qualify and periodically audit

- They are usually more open to sharing supply chain information

- They welcome building relationships with their customers

- They have formal processes in place for continuous improvement of their products, services, and processes

- Certification is done by an independent third party agency

- Firms have to be recertified every three years

Supplier Development

Supplier Development

- Supplier development - the technical and financial assistance given to existing and potential suppliers to improve quality and/or delivery performance

- Simply: it can be described as a buyer’s activities to improve a supplier’s capabilities

- A supplier’s knowledge and the technology that they use to produce the commodity they supply, can be leveraged through supplier development.

- Supplier development programs should be designed to achieve:

- Lower supply chain total cost

- Increased profitability for all supply chain participants

- Increased product quality

- Near-perfect on-time-delivery at each point in the supply chain

- Supplier development program must be aimed at improving supplier performance, not bullying them into charging less or simply auditing and rewarding them

- Supplier development is all about providing suppliers with what they need to be successful in the supply chain.

- Two of the most important functions of a supplier development program are:

- Providing information about products, expected sales growth, etc. Suppliers need to become extensions of their customers.

- Training suppliers in the application of lean and six sigma / quality tools.

- Asking suppliers to lower their price without giving them the knowledge on how to lower their costs is not sustainable in the long-term

Process - Typical Steps

- Identify critical products and services

- Identify the supplier of those critical products and services

- Form a cross-functional team internally to work with the supplier

- Identify what issues or gaps exist and what specific improvements need to be made

- Meet with the top management at the supplier to get their support and involvement

- Define details of the agreement and the action plan

- Monitor the status of the projects / action plan and modify strategies as necessary

Tapping into Strategic Supplier’s Knowledge

- Strategic sourcing partners offer the opportunity for a company to extend their intellectual capabilities by involving their external partner base in product development

- Early supplier involvement - Key suppliers become more involved in the internal operations of the buyer’s company, particularly with respect to new product and process design, concurrent engineering, and design for manufacturability.

- Strategic Suppliers are asked to add their knowledge and expertise to the company’s new product development process

- Value engineering - activities help the buyer’s company to reduce cost, improve quality and reduce new product development time beginning with the initial design

Supplier Recognition

Supplier Recognition Programs

- Supplier recognition program - A program to recognize suppliers who achieve the high performance standards necessary to meet customer expectations.

- It is always a good practice for a company to have innovative supplier recognition programs in order to recognize their achievements and rewards them for their exceptional performance and services.

- 3 attributes

- Companies should recognize and celebrate the achievements of their best suppliers.

- Award winners exemplify true partnerships, continuous improvement, organizational commitment, and excellence.

- Award-winning suppliers serve as role models for other suppliers

Benefits of Supplier Recognition Programs

- A properly developed and led Supplier Recognition Program will make major contributions to the organization, its suppliers, and to its customers and stakeholders

- Benefits:

- Motivate Suppliers – A Supplier Recognition Program can motivate suppliers to excel in terms of their quality, pricing and delivery commitments.

- If a company wants to retain and drive a supplier to excel, there should be a motivation plan designed to reach them.

- Improve Supplier Loyalty -Supplier support is important to ensure that customer delivery commitments are maintained

- Encourage Suppliers to Adapt to the Company’s Culture - If the company treats its suppliers as a part of the family and engages in supplier recognition programs periodically, it can help to bring the suppliers closer to the corporate values, ethics and principles of the company.

- Helps to Create Entry Barriers for Competitors - If the suppliers trust the company, they may be more inclined to sign deals of exclusivity with the company for certain crucial components.

- Encourages Supplier Participation in Product Innovation - Recognition to suppliers also brings about their enthusiasm to work closely with the company on new product development

- Motivate Suppliers – A Supplier Recognition Program can motivate suppliers to excel in terms of their quality, pricing and delivery commitments.

Supplier Relationship Management System

- Supplier relationship management system - provides a more comprehensive and objective view of a supplier(s) performance

- A system will help in identifying and addressing supplier performance issues.

- A system can also be used to help make sourcing decisions.

- It is important to recognize that an SRM system can only be implemented in line with the associated business process changes

- 5 key characteristics to consider in the development and implementation of an SRM system

- Automation is meant to handle routine transactions

- Integration spans multiple departments, processes, and software applications

- Visibility of information and clear and concise process flows

- Collaboration through information sharing

- Optimization of processes and decision making

Chapter 8: Operations Management with Lean and Six Sigma

Operations Management

- Operations management - managing the process to convert resources into goods and services in alignment with the company’s business strategy as efficiently and effectively as possible while also controlling costs

- The nature of how Operations Management is carried out varies by company and depends on the nature of the products or services in the portfolio

Manufacturing, Lean, and Six Sigma Definitions

- Manufacturing - to process or make raw materials or components into a finished product, especially by means of a large-scale industrial operation (i.e., mass production)

- Involves the entire process of converting raw materials or components into a finished goods item

- Includes the machines used, personnel involved, inventory handling, warehousing, etc.

- Manufacturing management - the management of all the processes which are involved in manufacturing

- Lean - an operating philosophy of waste reduction and value enhancement, improving the supply chain “flow”

- Six Sigma - a disciplined, statistical-based, data-driven methodology for identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and in business processes

- Improves the supply chain “process” by reducing variation

- Lean and Six Sigma complement each other

Manufacturing

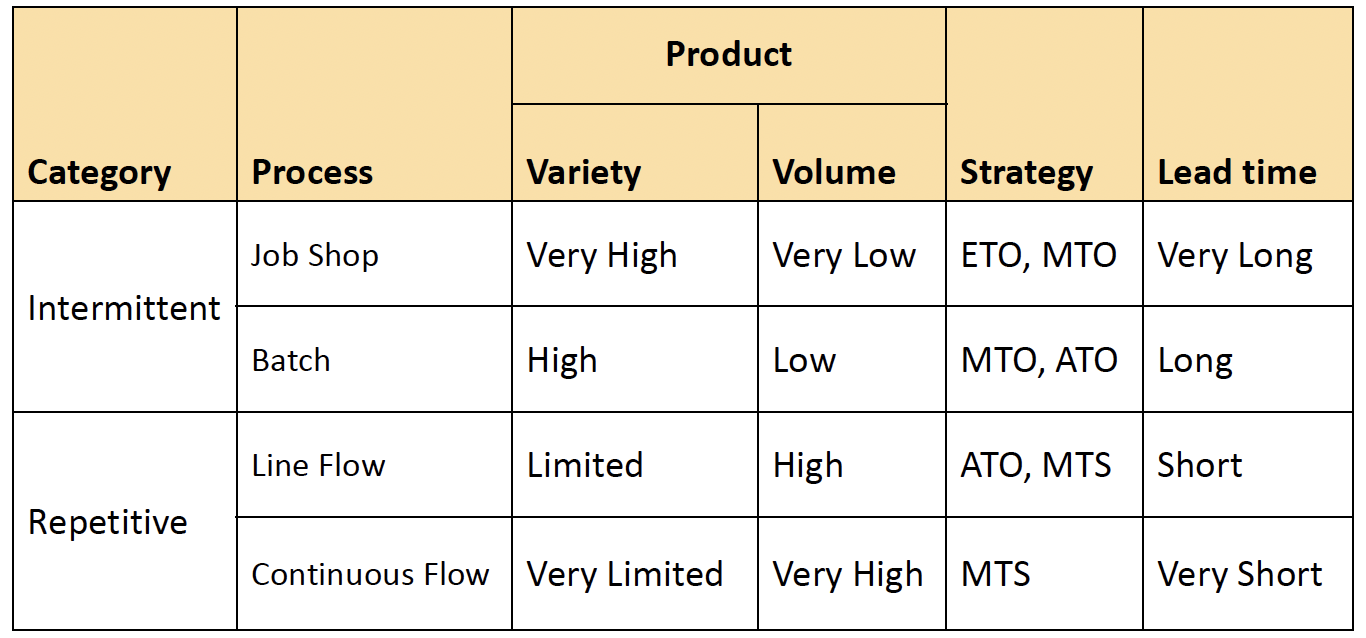

Major Manufacturing Strategies

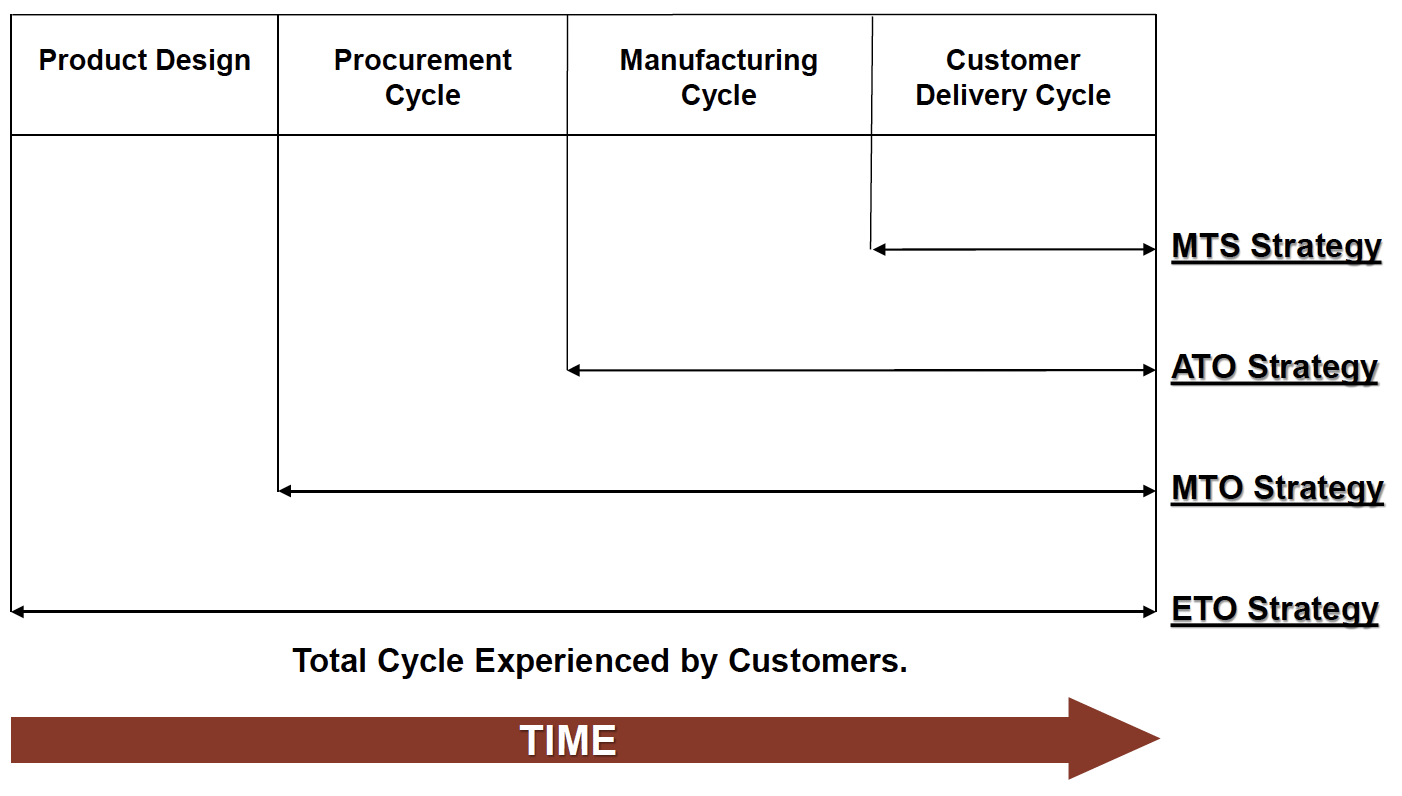

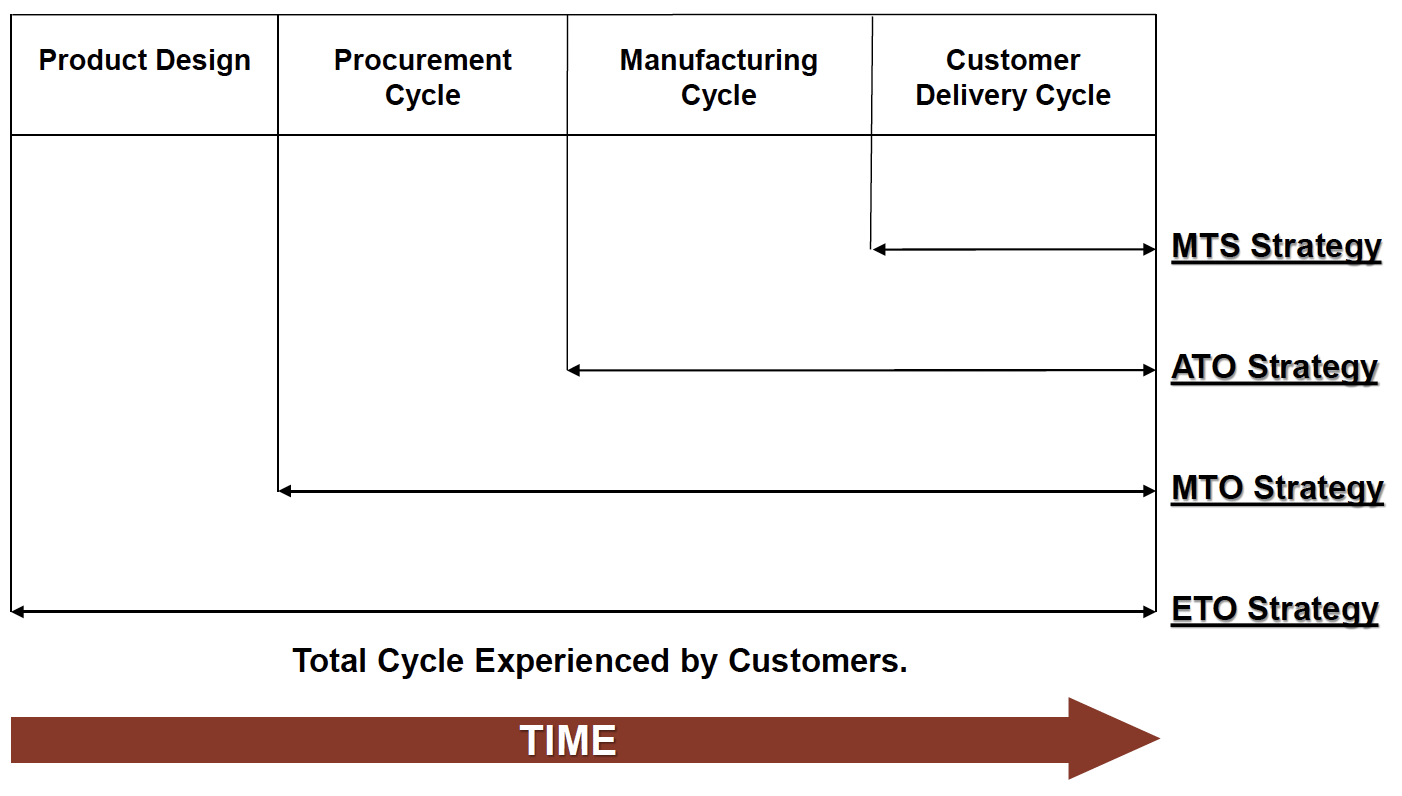

- Make-to-stock (MTS) - to manufacture products for stock based on demand forecasts. Push system

- Since accurate forecasts will prevent creating excess inventory and avoid stockouts, the critical issue is how to forecast demands accurately

- Most daily necessities such as food, sundries, and textiles are MTS-type products

- The challenge: to avoid having excess inventory

- Companies that operate with MTS model tend to hold more inventory just in case → they struggle to ensure that inventory levels don’t get out of control

- Make-to-order (MTO) - a manufacturing strategy in which manufacturing starts only after a customer’s order is received

- Creates additional wait time for the customer to receive the product but allows customers to purchase products that are customized to their specifications

- Relieves the problems of excessive inventory that is common with MTS strat

- MTO is not appropriate for all types of products

- Not appropriate for products where customers expect immediate availability/delivery

- Ex.: grocery items

- It is appropriate for highly configured products

- Ex.: aircraft, ocean vessels, bridges, or products that are very expensive to keep in inventory

- Not appropriate for products where customers expect immediate availability/delivery

- MTO is not appropriate for all types of products

- Assemble-to-order (ATO) - a manufacturing strategy where products ordered by customers are produced quickly and are customizable to a certain extent

- ATO strategy requires that the basic parts for the product are already manufactured but not yet assembled

- Once an order is received, the parts are assembled quickly into the finished product which is then sent to the customer

- Ex.: Dell laptops

- ATO is a hybrid strategy, combining the benefits of make-to-stock and make-to-order strategies, getting products into customers’ hands quickly while allowing for some customization to take place

- Engineer-to-order (ETO) - a manufacturing strategy in which the product is designed, engineered, and built to the customer’s specifications after receipt of the order

- A more dramatic evolution of make-to-order strategy

- ETO involves building a unique product every time

- There may be components that are common from one product to another, but the finished product is different each time

- Ex.: customized piece of manufacturing equipment

- In ETO world, the cost of poor quality can be very high

- The warranty costs and the cost of rework to replace an item in a complex assembly can have a serious negative effect on profit margins

Manufacturing Strategy vs. Performance Cycle

- Manufacturing strategy determines what cycle time (i.e., lead time) the customer will experience for delivery

Manufacturing Process

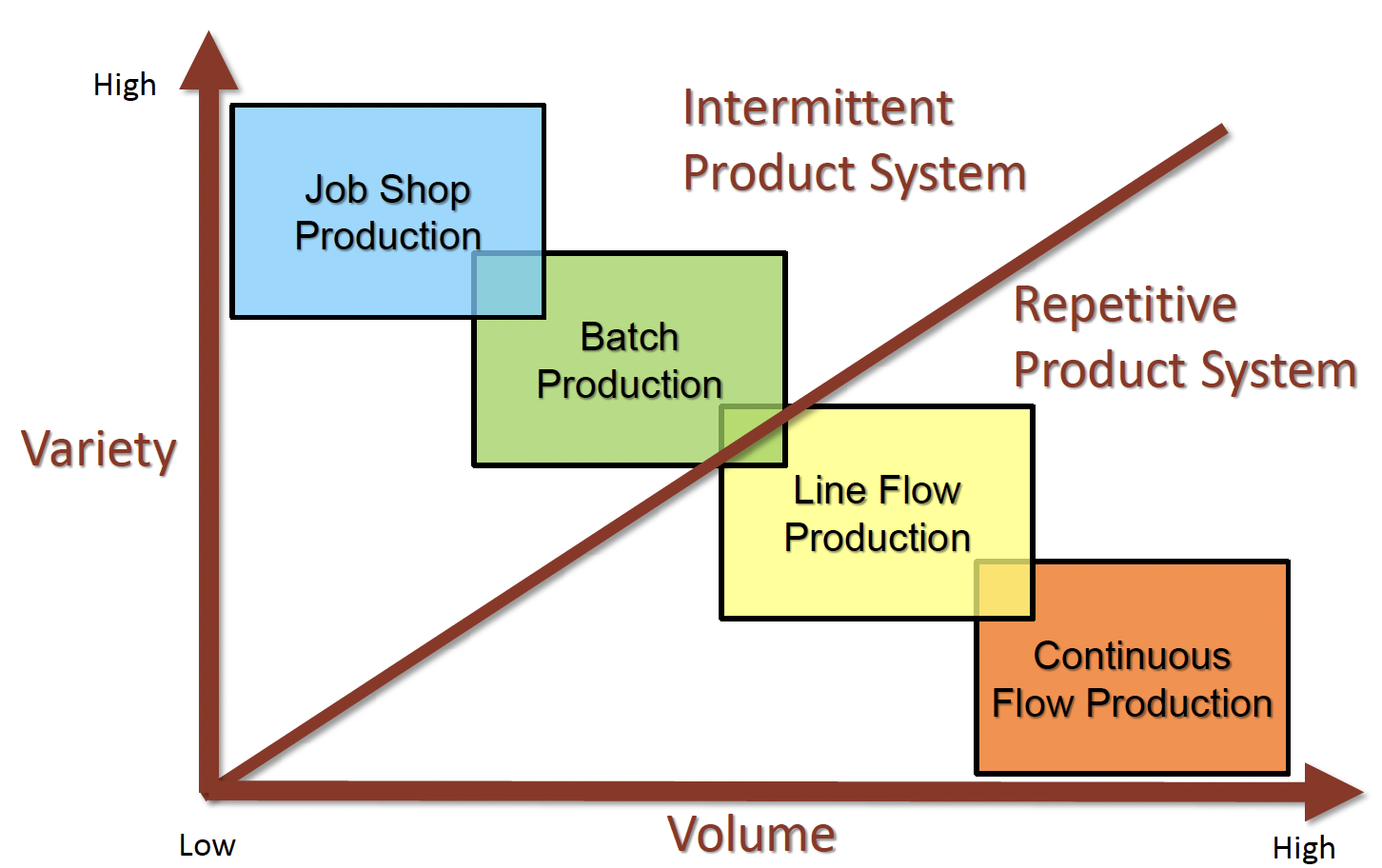

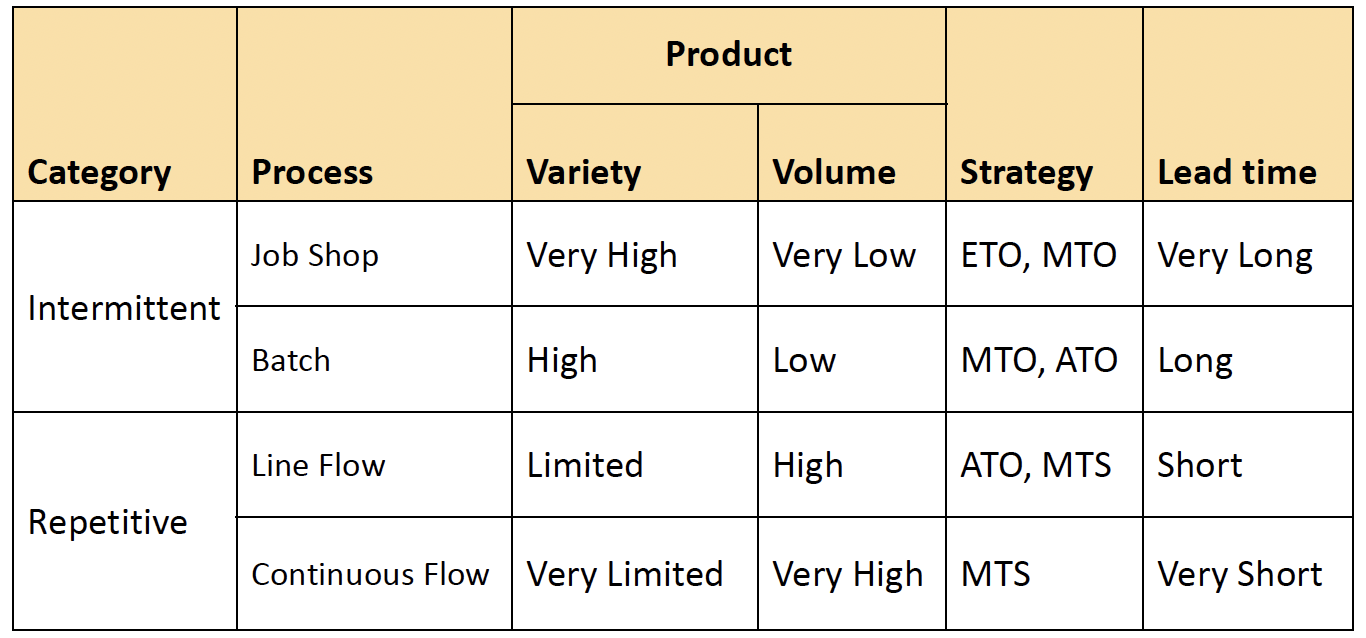

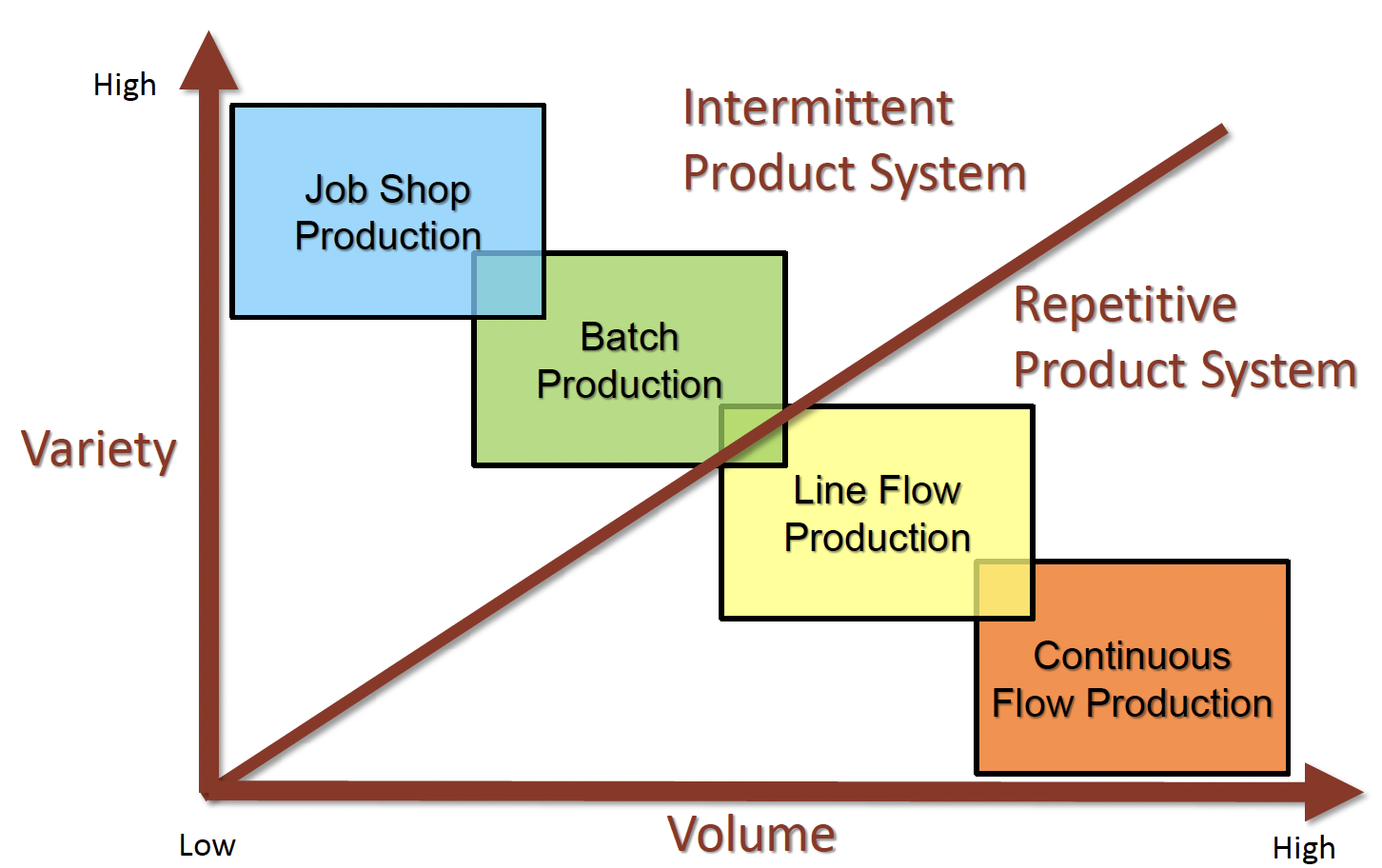

- Part of any manufacturing strategy involves developing a manufacturing process that can create the exact product that has been designed

- Although there are differences between companies, many manufacturing processes have certain characteristics in common

- Based on these characteristics, processes can be grouped into two broad categories:

- Intermittent processes - used to produce a large variety of products with different processing requirements in lower volumes

- Repetitive processes - used to produce one, or a few, standardized products in high volumes

Types of Manufacturing Processes

Job Shop Production (aka Project Production)

- Creates a custom product for each customer

- One-off or small number of items produced, generally one unit manufactured at a time

- High customization - normally made to custom specifications

- Often undertaken by small, specialist businesses

- Ex.: architects, ship builders, road builders

Batch Production

- Manufacturing of a small fixed quantity of an item in a single production run

- Each individual item in the batch goes through one stage of production process before the whole batch moves on to the next stage

- Aims to achieve better use of equipment

- Produces good quality products more economically than manufacturing them individually

- Ex.: bakeries; textiles; furniture; pharmaceuticals

Line Flow Production (aka Mass Production)

- For standardized products with a limited number of variations

- Product moves on an assembly line through various stages of production

- When one task is finished, the next task must start immediately → time taken on each task must be equal

- Ex.: automobile assembly; cell phones; toilet paper

Continuous Flow Production

- High capital investment - frequently dedicated to one specific product

- Involves a series of processes which raw materials flow through

- Processes are inflexible

- Generally highly automated and workers act as monitors rather than as active participants

- Typically, production runs 24 hrs a day with the end result being a large quantity of finished product

- Ex.: oil refining / gasoline; laundry detergent; cement; chemicals

Manufacturing Process vs. Manufacturing Strategy

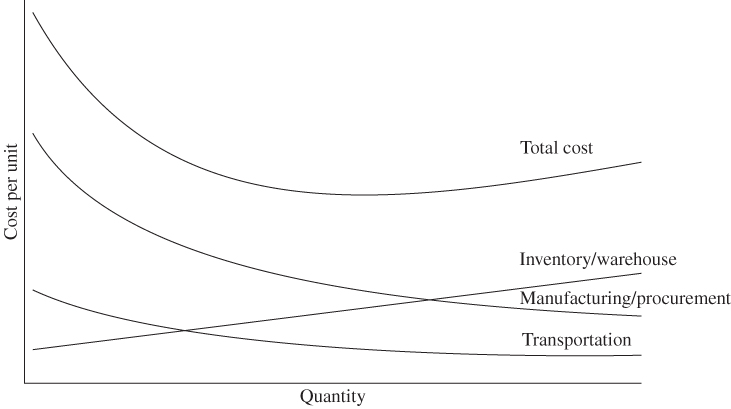

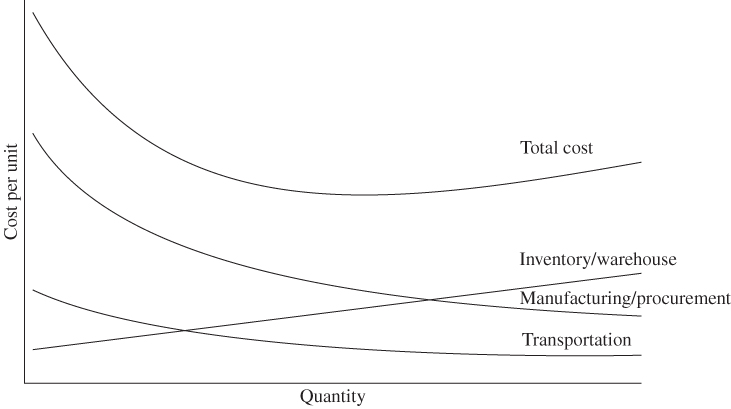

Total Cost of Manufacturing

- Total cost of manufacturing (TCM) - the complete cost of producing and delivering products to your customers

- Incorporates both fixed and variable costs used in manufacturing, storage, and delivery of the product

- TCM is generally expressed as cost per unit

- TCM includes:

- Manufacturing and Procurement activities

- Inventory and Warehousing activities

- Transportation activities

TCM vs. Strategic Alternatives

- As volume goes up:

- Manufacturing and Procurement costs go down due to economies of scale

- Generally, step function applies as more capital is required to produce

- Inventory and Warehousing costs go up

- Transportation costs go down, but level off at high volumes as the shipping container gets filled to capacity and another container must be used

- Manufacturing and Procurement costs go down due to economies of scale

Lean

Lean History

- 1990s: SCM combined:

- Quick Response -the rapid replenishment of a customer's stock by a supplier with direct access to data from the customer's point of sale

- Efficient Consumer Response (ECR) - a strategy to increase the level of services to consumers through close cooperation among retailers, wholesalers, and manufacturers.

- Just-in-Time (JIT) - an inventory strategy to decrease waste by receiving materials only when and as needed in the production process, thereby reducing inventory costs

- Keiretsu Relationships - involves companies both upstream and downstream of a manufacturing process, remaining independent but working closely together for mutual benefit

- The combo of these concepts have emerged as the philosophies and practices known as LEAN Manufacturing

What is Lean?

- Lean - a management philosophy based on the Toyota Production System (TPS)

- Objective

- Eliminate everything that does not add value (i.e., waste) in the customer’s eyes

- Focus and scope

- Using Value Stream Mapping as primary work unit

- Focusing on improving process performance

- Having a clear view of the end state

- Approach and tools

- A wide range of LEAN tools are available

- Learn-by-doing approach to performance improvement and capability-building

Value Stream Map

- Value stream map - shows the information flows from the customer to the supplier, which drive material flow back to the customer in response to their requirements, using people and process interactions

What Lean is NOT

- Laying off employees by the bus load

- Delivering less or working harder

- Outsourcing or offshoring

- A cost reduction program

- Just a set of “tools” like 5S, kaizen events, etc.

- Automation or buying a monstrous ERP system

- Winning a Shingo Prize so as to look Lean

- A toolbox of methods, ideas, or methodologies

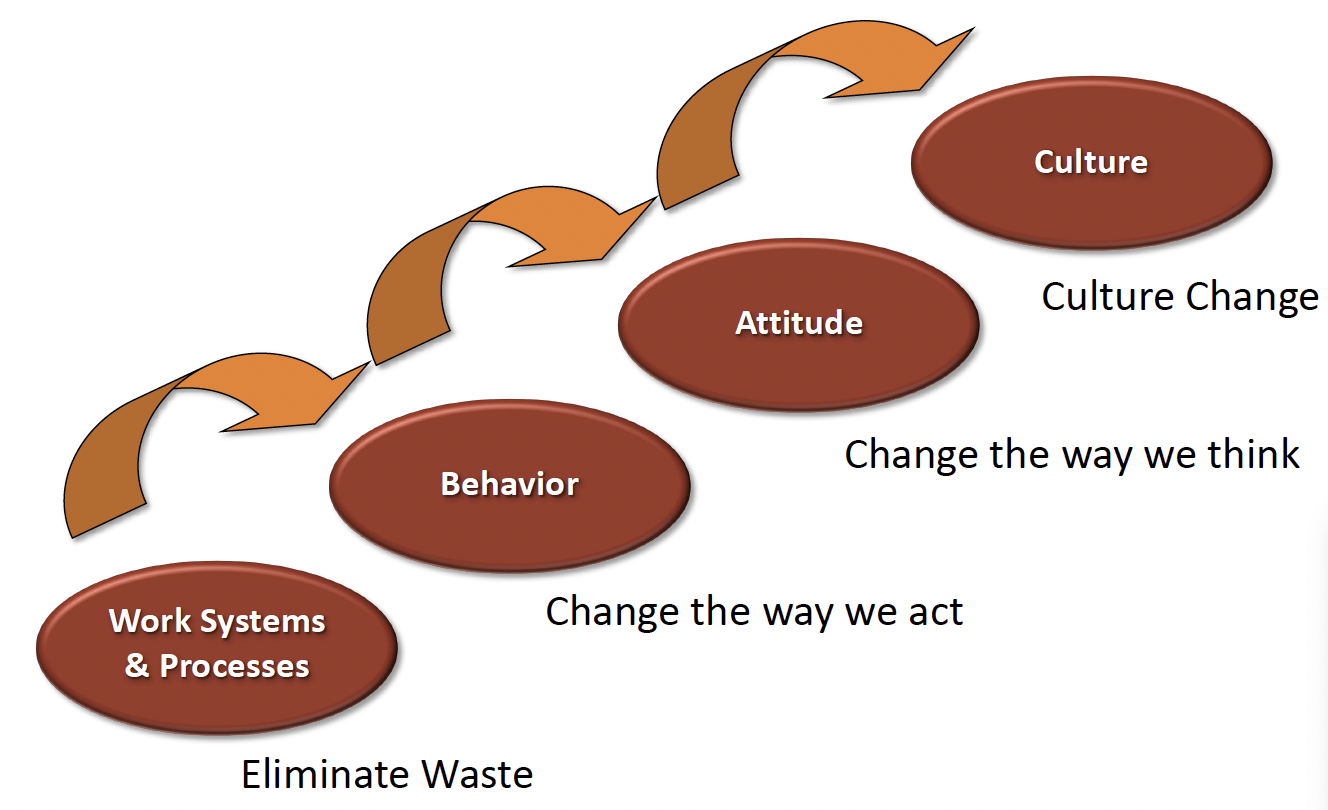

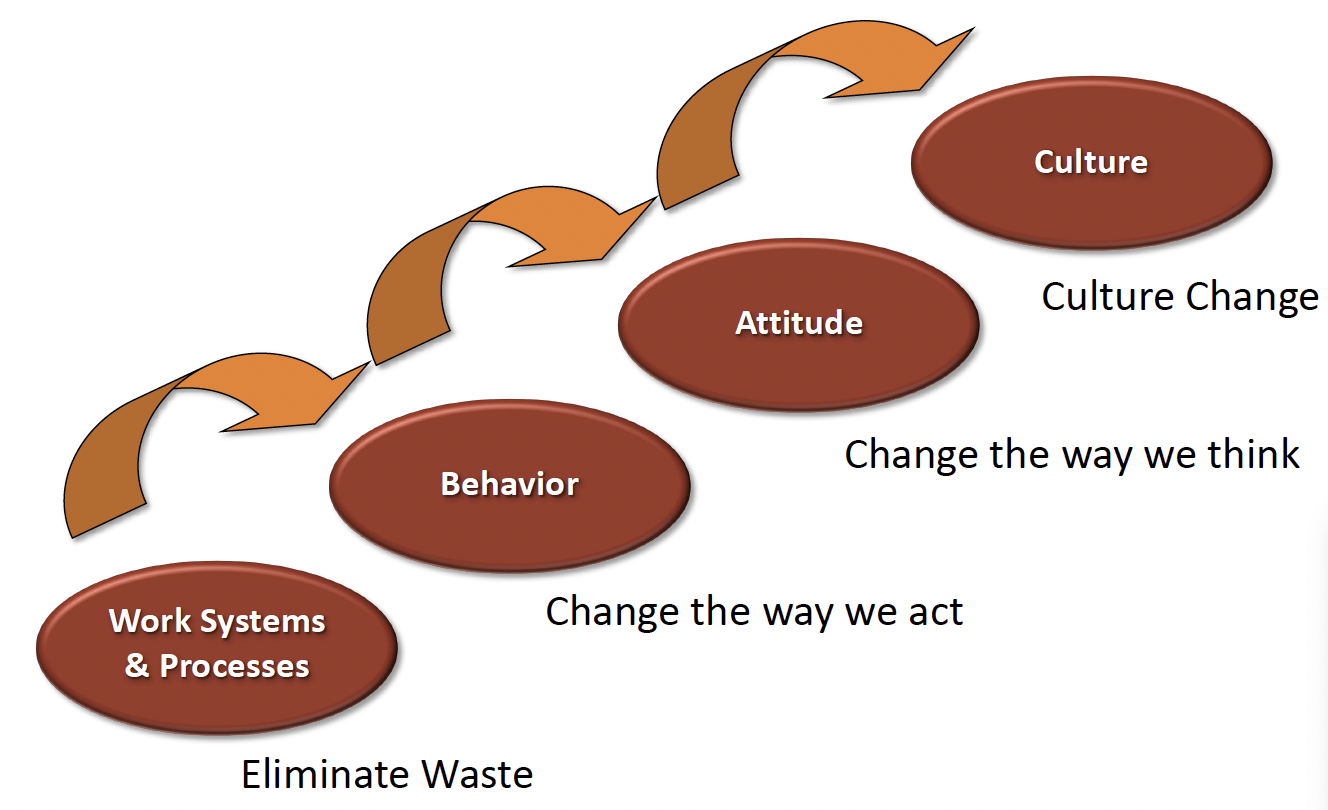

Lean Facilitates a Culture Change

What Lean IS

- Lean is standard in many industries

- Lean regularly results in:

- Large cost reductions

- Improved quality

- Increased customer service

- Goal of Lean: elimination of waste and the minimization of the amount of all resources used in the operation of a company

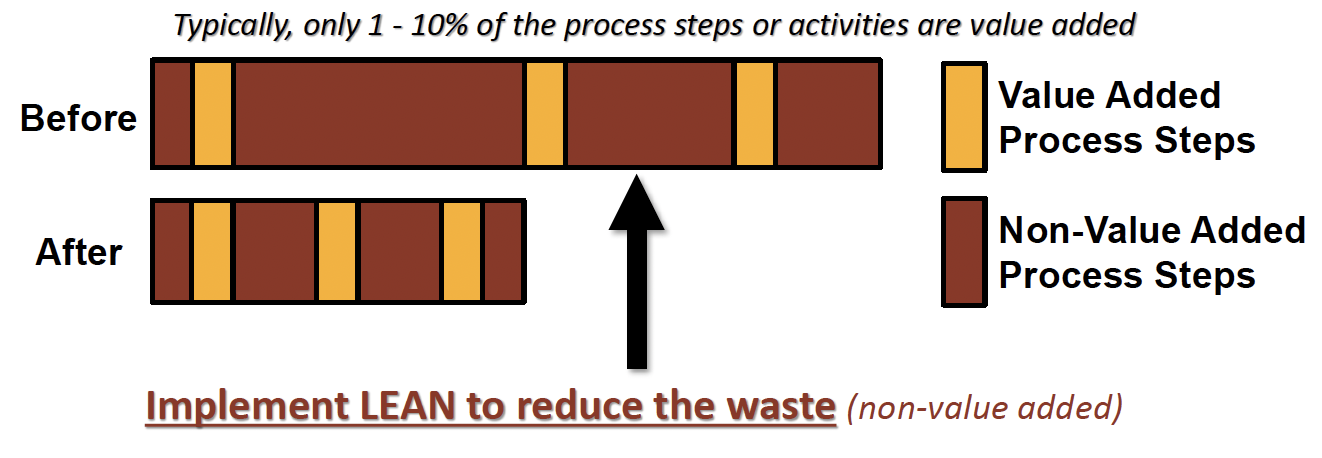

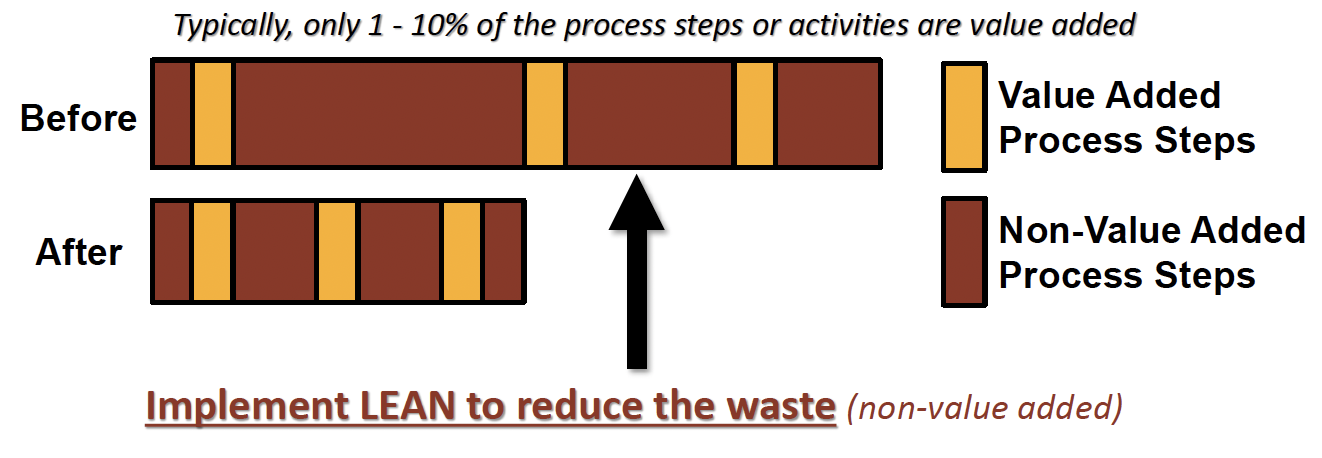

Understand “Value”

- Value - the inherent worth of a product as judged by the customer and reflected in its selling price and market demand

- It is any activity that increases the market, form, or function of the product/service

- Things for which the customer is willing to pay

- Value added process - process steps that transform or shape a product or service which is eventually sold to a customer

- Non-value added process - process steps that take time, resources, or space, but do not transform or shape the product or service

Elements of Lean Manufacturing

Components of Lean

- Lean is composed of 3 components working in unison:

- Lean manufacturing

- Respect for people

- Total quality management

A. Lean Manufacturing

- Lean manufacturing - a natural fit within the discipline of SCM as all of the Lean goals and objectives help to facilitate an efficient and effective supply chain

- Satisfying internal customer demand

- Communicating demand forecasts and production schedules up the supply chain

- Quickly moving products in the production system

- Optimizing inventory levels across the supply chain

- Increasing the value, capabilities, and flexibility of the workforce through cross-training

- Extending collaboration and alliances beyond just 1st tier suppliers and customers to include 2nd and 3rd tier suppliers and customers as well

Elements of Lean Manufacturing

- Waste Reduction

- LEAN Layouts

- Inventory, Setup Time, & Changeover Time Reduction

- Small Batch Scheduling and Uniform Plant Loading

- LEAN Supply Chain Relationships

- Workforce Empowerment

- Continuous Improvement

1. Waste Reduction

- Firms reduce costs and add value by eliminating waste from the production system

- Waste encompasses:

- wait times

- Inventories

- material and people movement

- processing steps

- Variability

- any other non-value-adding activity

- After waste is removed, processes are more streamlined, resulting in more satisfied customers. You’ll also save your organization time and money

- 8 waste categories: DOWN TIME

- Defects - Work not done right the first time such as scrap and rework

- Overproduction - Producing sooner, faster or in greater quantities than customer demand

- Waiting - People or parts that wait for a work cycle to be completed

- Non-utilized talent - Not using employees full intellectual contribution

- Transportation - Unnecessary movement of materials or parts between processes

- Inventory - Raw material, WIP or finished goods which is not having value added to it

- Motion - Unnecessary movement of people, or multiple hand-offs

- Extra-processing - Processing beyond the standard required by the customer

- Benefits of Lean waste reduction

- Reducing waste consequently results in:

- Reduced cycle times

- Greater throughput

- Better productivity

- Improved quality

- Reduced costs

- All these can improve customer satisfaction and provide the company with a competitive advantage

- Reducing waste consequently results in:

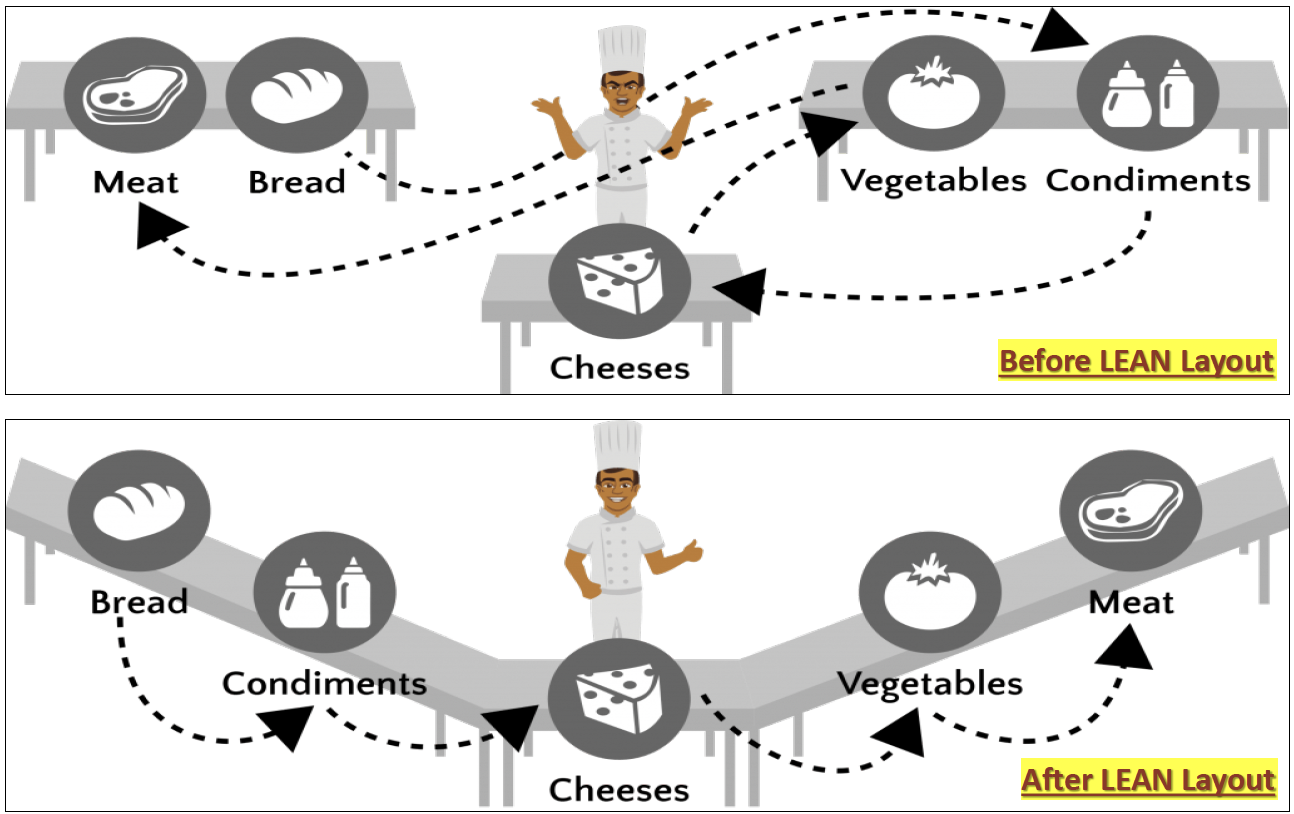

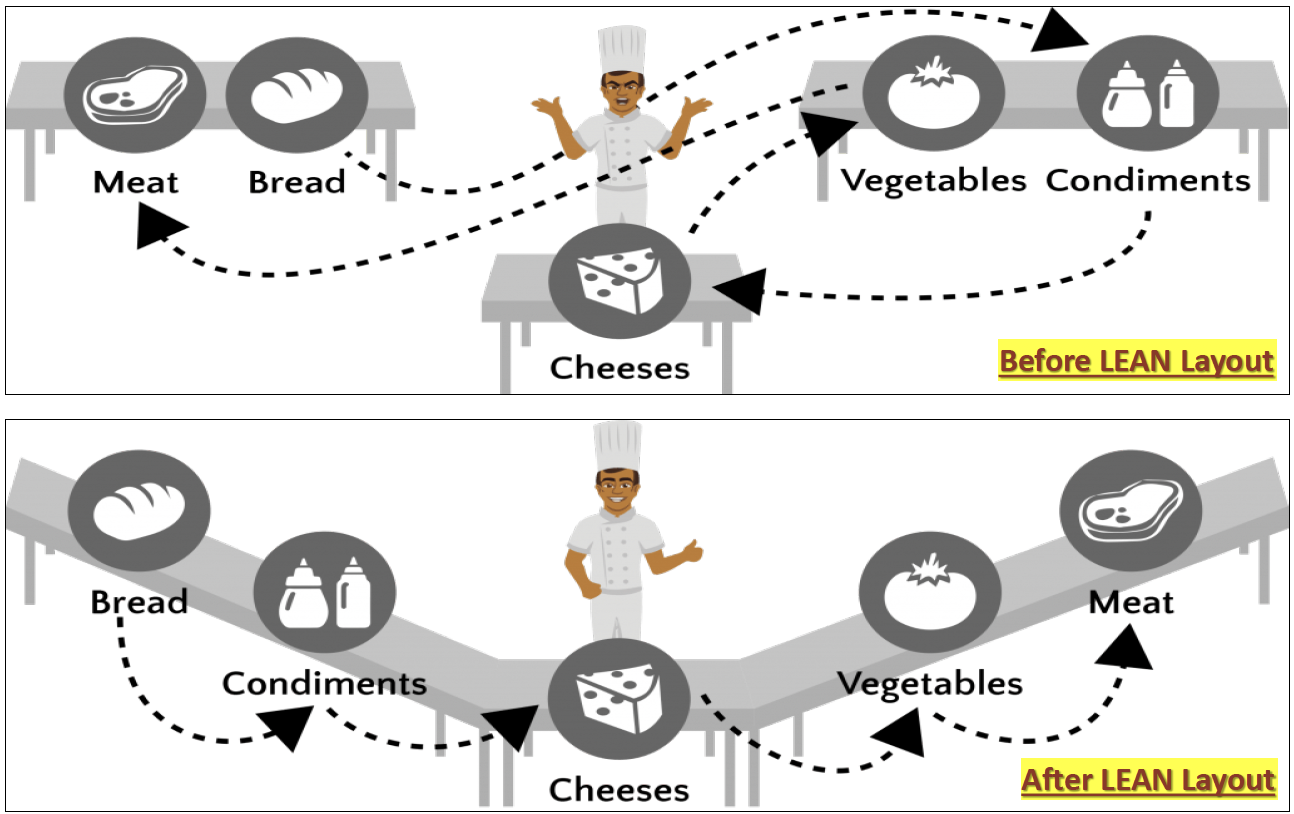

2. Lean Layout

- Move people and materials when and where needed, and as soon as possible

- Are very visual (lines of visibility are unobstructed) with operators at one processing center able to monitor work at another

- Manufacturing cells

- Process similar parts or components saving duplication of equipment and labor

- Are often U-shaped to facilitate easier operator and material movements

- Sandwich shop example

- McDonalds - Speedee Service System example

- Richard "Dick" (1909-1998) and Maurice "Mac" (1902-1971) McDonald first opened their restaurant in 1940, but re-created it in 1948 on the model of their "SpeedeeService System"

- Speedee Service System applied the principles of a LEAN layout to fast food preparation and formed the foundation of what Ray Kroc would later leverage into the world’s largest food outlet chain, McDonalds

- The 5 S’s

- 5-S - a systematic process of workplace organization

- 5 pillars of the visual workplace

- Focuses on effective workplace organization and standardization. Allows us to easily spot variation from standard operating conditions

- Sort - Keep only necessary items in the workplace, eliminate the rest

- Set in Order - Organize and arrange items to promote an efficient workflow

- Shine - Clean the work area so it is neat and tidy

- Standardize - Schedule regular cleaning and maintenance

- Sustain - Stick to the rules. Maintain and review the standards

- Results in

- Cleaner, safer work environment

- Organized, user friendly workstations

- Open up space and reduce clutter

- 5-S - a systematic process of workplace organization

3. Inventory, Setup Time, and Changeover Time Reduction

- Some inventory may be necessary, but excess inventory is waste

- Excess inventory takes up space and costs money to hold, maintain, protect, secure, and insure

- It ties up financial capital which could be used for other business aspects

- Reducing inventory can free up capital and reduce holding costs

- There is less likelihood of waste being created by obsolescence, expiry, spoilage, or damage with lower inventory levels

- Pull system

- Traditional approach - supply chains work as “push” systems, and inventory is carried to cover up problems

- Pull approach - each stage in the supply chain requests quantities needed from the previous stage

- No excess inventory generated

- Reducing inventory levels can also uncover production problems

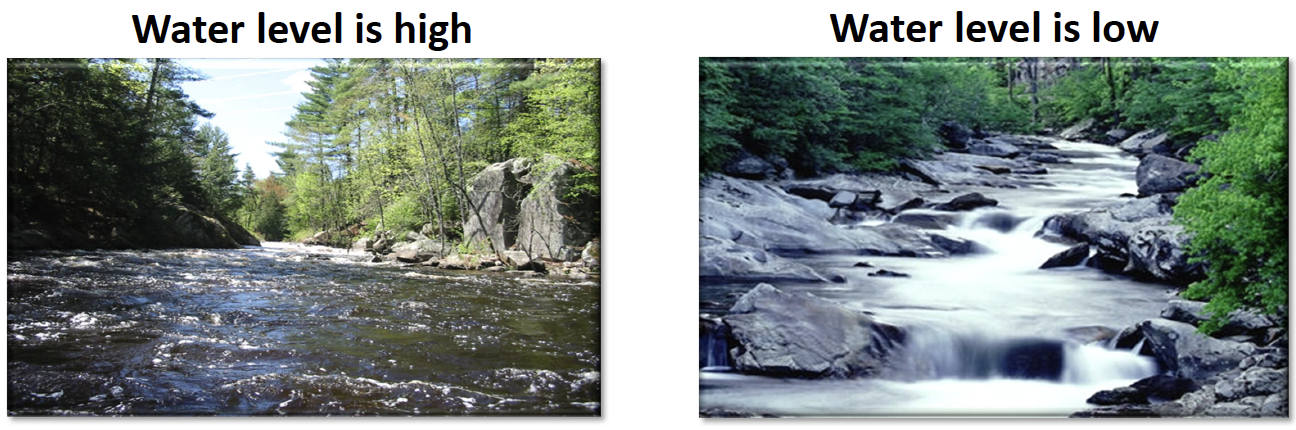

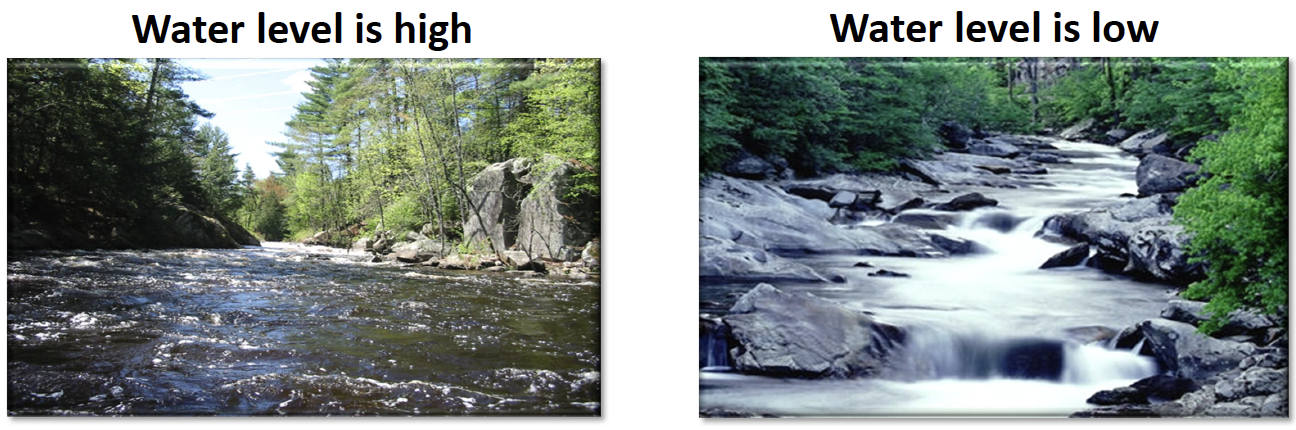

- Water analogy

- Water represents inventory

- High water level: you don’t see the rocks beneath the surface, so you may not know they are there

- Rocks represent hidden obstacles and issues

- Inventory can hide underlying problems, but they are still there and can potentially create major issues in the supply chain

- Lowering inventory: helps expose the hidden problems

- Once problems are detected, they can be solved

- End result: smoother running supply chain with less inventory investment

- Setup time and changeover time are both considered waste as they are times when the equipment is not performing its intended function—producing product

- Setup time - the time taken to prepare and format the manufacturing equipment and systems for production

- Changeover time - the time taken to adapt and modify the manufacturing equipment and systems to produce a different product or a new batch of the same product

- While setting up the equipment is a necessary function, if the setup time can be minimized, the difference will be more time available to produce

- Both setup and changeover are non-value added operations and should be minimized as much as possible

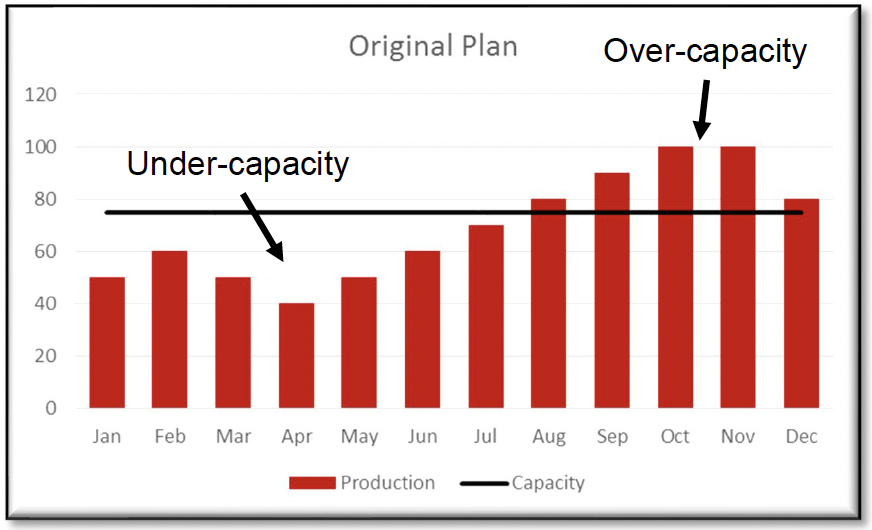

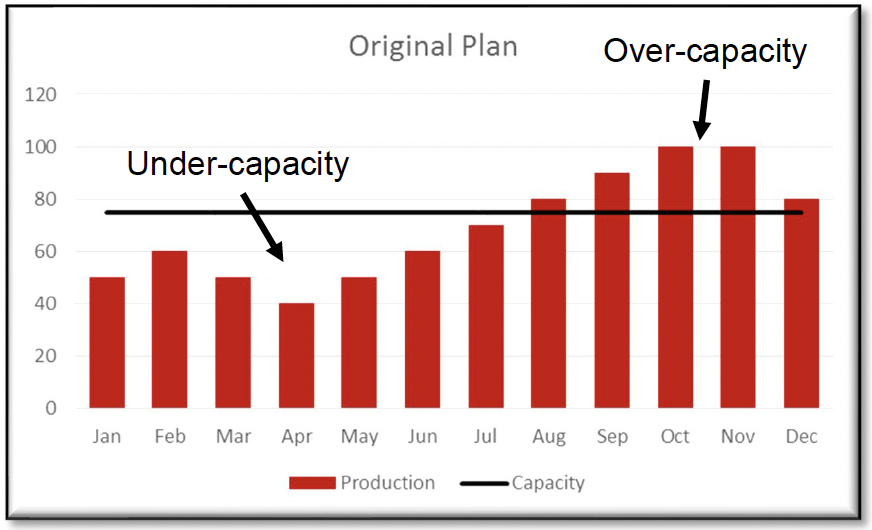

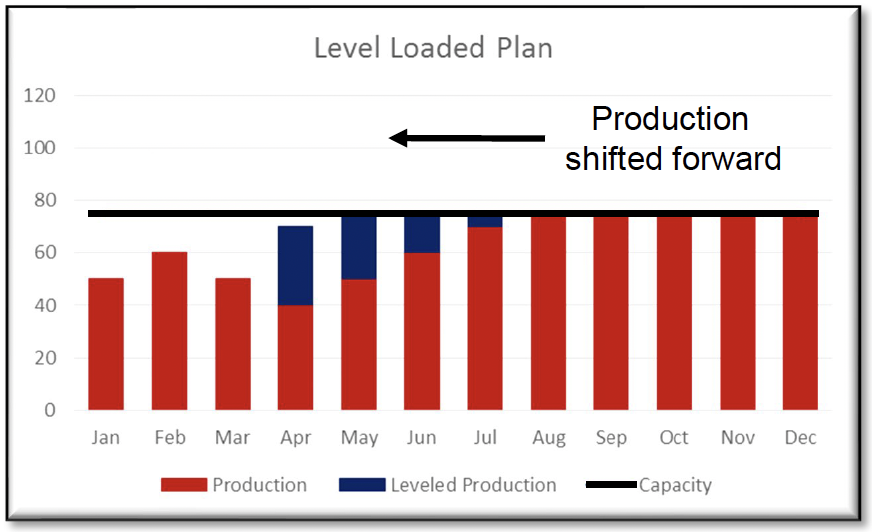

4. Small Batch Scheduling and Uniform Plant Loading

- The ideal schedule is to produce every product as quickly as possible and at the same rate as customer demand.

- In the real world, material availability, labor availability, and setup or changeover time influences the scheduling of large batches

- Large batches can exacerbate the Bullwhip Effect as production in large batches creates an uneven workload

- Production is not synchronized with customer demand, making a pull system impossible.

- Throughput (i.e., amount of material or items passing through a system or process) times in manufacturing go up, and work-in-process inventory goes up, creating more waste in the system.

- Think of a snake trying to swallow a large meal

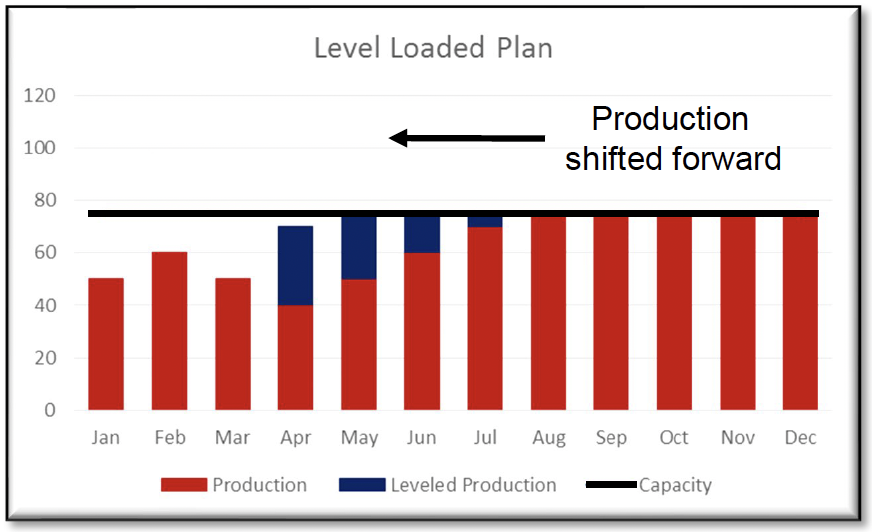

- Small batch scheduling

- Lean manufacturing attempts to reverse this through small batch scheduling

- Smaller batches will facilitate producing at the same rate as customer demand

- Production in small batches creates a smooth workload as production can be synchronized with customer demand, facilitating a pull system